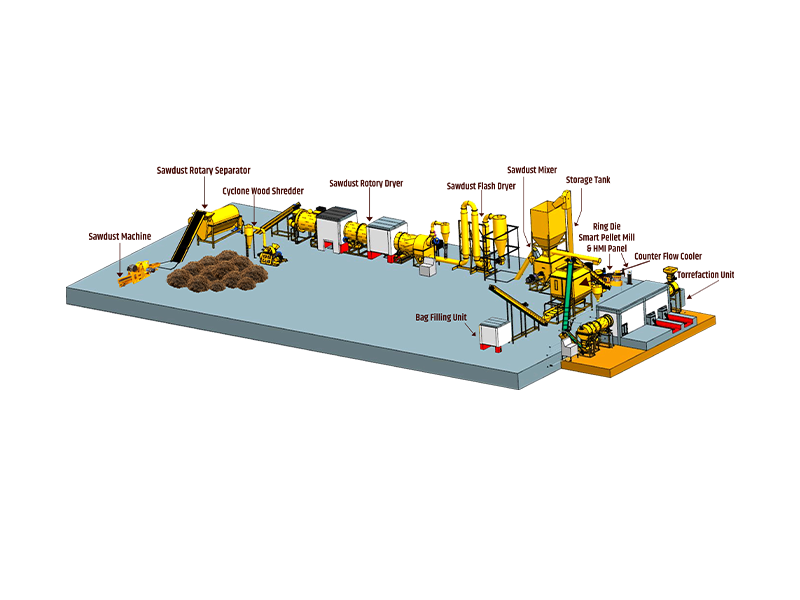

Versatile and efficient solution for converting biomass waste into high-quality pellets. Ideal for small-scale production, this machine features a compact design, user-friendly operation, and energy efficiency. It processes materials like sawdust, agricultural residues, and forestry waste into durable biomass pellets, suitable for fuel or animal feed. Perfect for eco-friendly operations and sustainable energy solutions.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| BM250 | 250KG/Hour | 55 HP | 30 x 45 x 20 |

| BM500 | 500KG/Hour | 80 HP | 40 x 50 x 20 |

| BM1000 | 1000 KG/Hour | 145 HP | 40 x 60 x 25 |

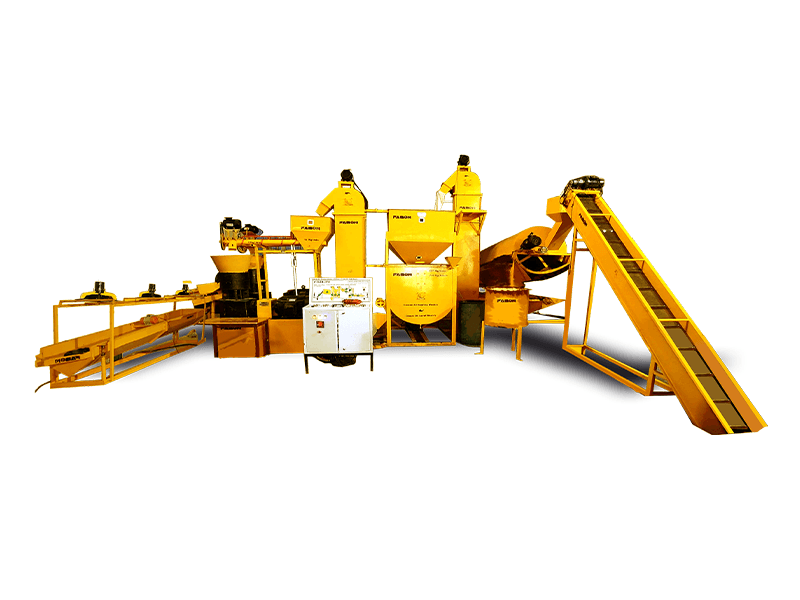

Compact, Cost-Effective Pelletizing Solution for Small to Medium-Scale Biomass Projects

FABON Engineering’s Biomass Pellet Flat Die Plant is an efficient and economical system designed to convert sawdust, wood chips, agro-waste, and crop residues into high-quality biomass fuel pellets. Using a Flat Die Pellet Mill, this plant is ideal for startups, rural entrepreneurs, and small-scale industries looking to adopt sustainable fuel solutions.

✅ Key Features:

Capacity Range: 100 Kg/hr to 1000 Kg/hr

Flat Die Pellet Mill: Simple design with low operating cost

User-Friendly Operation: Easy to run, maintain, and transport

Multi-Material Capability: Handles sawdust, rice husk, straw, groundnut shells, and more

Diesel or Electric Driven Options: Suitable for remote or off-grid locations

Low Maintenance Design: Minimal moving parts and sturdy construction

🌾 Ideal For:

Small biomass fuel producers

Village-level entrepreneurs

Farmer Producer Companies (FPCs)

Rural and off-grid pellet production

Domestic and semi-industrial fuel use

🔧 Plant Includes:

Raw Material Crusher or Grinder

Optional Flash Dryer (for high-moisture inputs)

Flat Die Pellet Mill with Screw Feeder

Cooling & Screening Unit (optional)

Manual or Semi-Automatic Bagging System

🌿 Why FABON Engineering:

Proven, rugged machine design

Custom-built systems with on-site setup

Spare parts & service support

One-year warranty & AMC available