Showing all 8 results

- Sale!

Add to cart

Add to cartBiomass Flat Die Pellet Plant – Compact, Cost-Effective Pelletizing for Small to Medium Scale Production What is a Biomass Flat Die Pellet Plant? A Biomass Flat Die Pellet Plant is a compact and efficient solution for converting various types of biomass—such as sawdust, rice husk, straw, coconut shell, and agricultural residues—into solid biofuel pellets. Using…

Read more

Read moreVersatile and efficient solution for converting biomass waste into high-quality pellets. Ideal for small-scale production, this machine features a compact design, user-friendly operation, and energy efficiency. It processes materials like sawdust, agricultural residues, and forestry waste into durable biomass pellets, suitable for fuel or animal feed. Perfect for eco-friendly operations and sustainable energy solutions.

Model Capacity Motor Plant Size BM250 250KG/Hour 55 HP 30 x 45 x 20 BM500 500KG/Hour 80 HP 40 x 50 x 20 BM1000 1000 KG/Hour 145 HP 40 x 60 x 25  Add to cart

Add to cartFABON Biomass Pellet Making Machine: Advanced Solutions for Sustainable Energy Introduction In a world increasingly driven by sustainable energy solutions, the FABON Biomass Pellet Making Machine stands out as a cutting-edge innovation in renewable energy technology. Designed for efficiency, durability, and scalability, this machine is ideal for entrepreneurs, agro-industrial businesses, and renewable energy firms seeking…

Read more

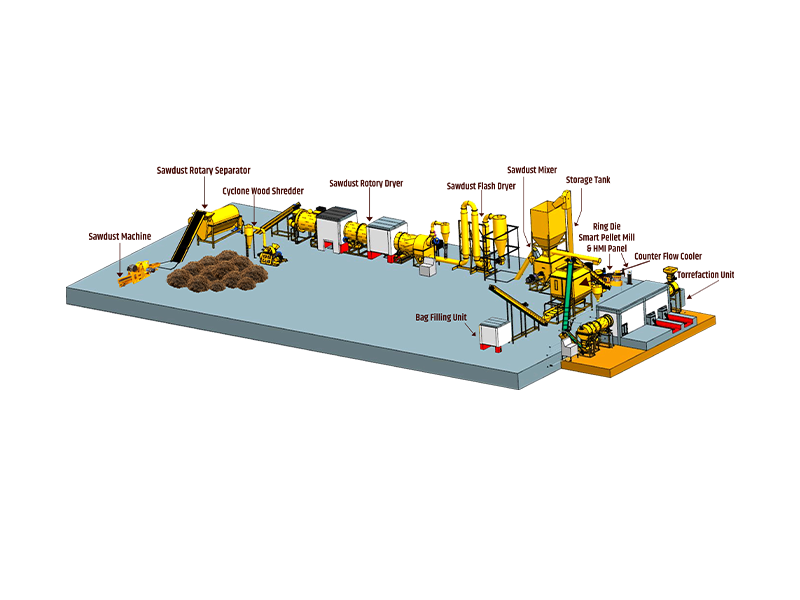

Read moreA Biomass Pellet Torrefaction Plant is an advanced facility designed to process biomass into torrefied biomass pellets, which are superior in energy content, durability, and transportability. This plant uses a controlled thermal process called torrefaction, where raw biomass materials such as wood chips, agricultural waste, or forestry residues are heated at temperatures ranging from 200°C to 300°C in the absence of oxygen.

Key Features of a Biomass Pellet Torrefaction Plant:

- Torrefaction Process:

- Feedstock Flexibility:

- Pelletizing System:

- Smart Automation:

- Environmental Benefits:

- Energy Efficiency:

Applications of Torrefied Biomass Pellets:

- Energy Production: Used in power plants as a green substitute for coal in co-firing or standalone combustion.

- Industrial Heating: Suitable for industries requiring high-energy fuels for boilers and kilns.

- Household Use: Ideal for heating systems and stoves due to their high energy density.

Why Choose FABON for Your Biomass Pellet Torrefaction Plant?

- Engineering Excellence: FABON Engineering Pvt. Ltd. specializes in designing robust, efficient, and eco-friendly torrefaction plants tailored to client needs.

- Sustainability Focus: Our solutions align with global goals for clean energy and carbon neutrality.

- Smart Technology: With automated systems and real-time reporting, FABON ensures seamless operation and optimized performance.

- After-Sales Support: Comprehensive service, maintenance, and troubleshooting assistance.

- Sale!

Add to cart

Add to cartBiomass Torrefaction Pellet Plant: Revolutionizing Renewable Energy Production What is a Biomass Torrefaction Pellet Plant? A Biomass Torrefaction Pellet Plant is an advanced bioenergy production facility designed to convert raw biomass—such as agricultural residues, wood chips, and organic waste—into torrefied biomass pellets. These black pellets are a superior solid biofuel with enhanced energy density, hydrophobic…

Add to cart

Add to cartFABON Flash Dryer: Fast, Efficient Drying Technology for High-Performance Industries Introduction In today’s high-speed industrial environment, efficient drying solutions are essential to improve product quality, increase production speed, and reduce operational costs. The FABON Flash Dryer represents the next generation of drying technology, offering rapid moisture removal, minimal thermal degradation, and maximum energy efficiency. Engineered…

Read more

Read moreAn advanced, fully automated solution for large-scale biomass pellet production. Equipped with a smart operating system, HMI panel, and real-time mobile monitoring, it ensures precision, efficiency, and seamless operation. Designed to process diverse biomass materials into high-quality pellets, it offers process optimization, data analysis, and after-sales service support for sustainable energy and industrial applications.

Model Capacity Motor Plant Size RD700 700KG/Hour 150 HP 15 x 45 x 20 RD1000 1000KG/Hour 204 HP 15 x 55 x 20 RD2000 2000 KG/Hour 348 HP 20 x 70 x 25 RD3000 3000 KG/Hour 506 HP 20 x 90 x 25 RD4000 4000 KG/Hour 670 HP 20 x 90 x 30 RD5000 5000 KG/Hour 847 HP 25 x 100 x 30 RD6000 6000 KG/Hour 940 HP 30 x 100 x 30 - Sale!

Add to cart

Add to cartYULONG Biomass Pellet Making Machine – Precision Pelletizing for the Future of Renewable Energy Introduction: Leading the Biomass Revolution with YULONG In the global shift toward sustainable energy, biomass pellet production has become a critical technology for reducing dependence on fossil fuels. As industries, power plants, and heating systems transition toward greener energy, the demand…