🌑 Turning Waste Into Black Gold: Torrefaction Biomass Pellet Plant by Fabon Engineering, Nashik

In the evolving landscape of renewable energy, torrefied biomass pellets are gaining global attention for their superior fuel properties. At the forefront of this innovation in India is Fabon Engineering Pvt. Ltd., Nashik, with its state-of-the-art Torrefaction Biomass Pellet Plant—a pioneering solution that upgrades raw biomass into high-efficiency, carbon-rich biofuel.

🔥 What Is Torrefaction?

Torrefaction is a thermal pre-treatment process in which biomass is heated to 200–300°C in a low-oxygen environment. This drives off moisture and volatile compounds, transforming the biomass into a blackened, coal-like substance known as torrefied biomass—or more commonly, bio-coal.

When pelletized, this material becomes a high-energy, water-resistant fuel with properties close to lignite coal—making it an eco-friendly substitute in industrial boilers, power plants, and even cement kilns.

🏭 Fabon’s Torrefaction Biomass Pellet Plant: Key Highlights

✅ Integrated Plant Design

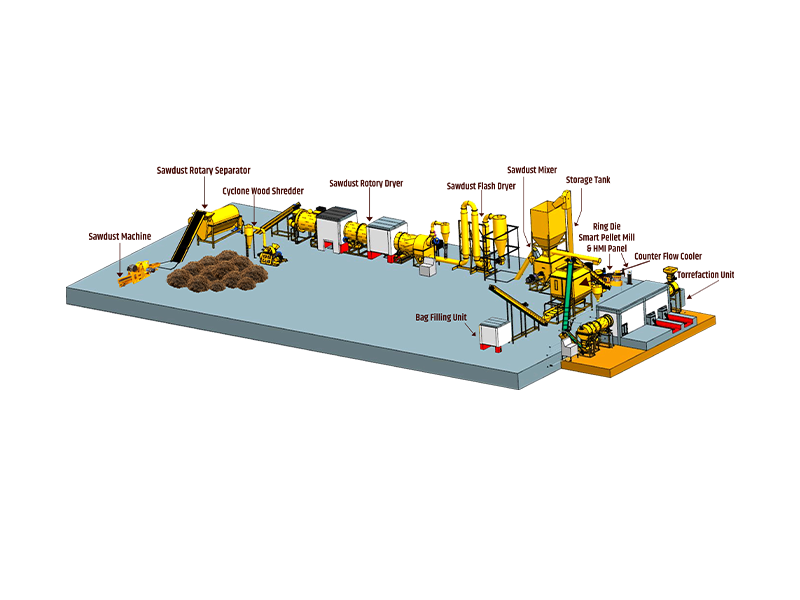

Fabon offers a modular plant setup that combines:

Biomass drying system

Torrefaction reactor

Cooling chamber

Pelletizing unit

Dust & gas handling systems

✅ High-Quality Output

Energy-dense pellets (18–22 MJ/kg)

Hydrophobic & non-brittle structure

Low ash and sulfur content

Ideal for co-firing with coal in thermal power plants

✅ Feedstock Flexibility

Capable of processing a variety of Indian agro-waste and woody biomass such as:

Rice husk

Bamboo

Sugarcane bagasse

Corn stalk

Sawdust

Coconut shells

🔧 Technical Specifications (Sample Line)

| Section | Capacity Range | Power Requirement |

|---|---|---|

| Torrefaction Unit | 0.5 to 2 TPH | 50 – 100 HP |

| Pelletizer | 500 – 2000 kg/hr | 25 – 75 HP |

| Dryer | Custom (based on input) | 20 – 60 HP |

Note: Fabon customizes the plant size based on available biomass and client requirements.

🌱 Applications

Coal Replacement: Cleaner energy for cement, brick kilns, and thermal power plants.

Export Quality Biofuel: High-calorific-value pellets for global markets.

Carbon Credits: Helps industries lower carbon footprints and qualify for sustainability benefits.

Waste Valorization: Converts low-value residues into profitable fuel.

🇮🇳 Why Choose Fabon Engineering?

🛠️ Make-in-India Manufacturing with global standards

🔧 Turnkey Project Solutions: From design to commissioning

📦 Custom Fabrication to suit diverse biomass inputs

🧑🔧 On-site Installation, Training & AMC

⚙️ Availability of Spare Parts & After-Sales Support

🌍 Support for carbon credit certification and exports

❓ FAQ: Torrefaction Biomass Pellet Plant by Fabon Engineering, Nashik

1. What is a torrefaction biomass pellet plant?

A torrefaction biomass pellet plant processes raw biomass through a controlled thermal treatment (torrefaction), turning it into a coal-like material called torrefied biomass or bio-coal. This material is then pelletized to create a high-energy, water-resistant renewable fuel.

2. How is torrefied biomass different from regular biomass pellets?

| Feature | Regular Biomass Pellets | Torrefied Biomass Pellets |

|---|---|---|

| Energy Value | ~14–16 MJ/kg | ~18–22 MJ/kg |

| Water Resistance | Low | High |

| Storage Stability | Moderate | Excellent |

| Carbon Content | Lower | Higher |

| Ideal Use | Domestic & agro use | Industrial fuel, export |

3. What raw materials can be used for torrefaction?

The plant can process a wide variety of agricultural and forestry residues, including:

Rice husk

Bamboo

Coconut shells

Sugarcane bagasse

Wood chips

Sawdust

Corn stalks

Fabon can tailor the system for your local feedstock availability.

4. What are the key benefits of torrefied biomass pellets?

🔥 Higher calorific value (closer to coal)

💧 Moisture resistance for outdoor storage

🌍 Reduced carbon footprint compared to coal

🏭 Ideal for co-firing in coal-based power plants

💰 Eligible for carbon credits and green energy incentives

5. What is the typical capacity of Fabon’s torrefaction pellet plants?

| Unit | Capacity Range |

|---|---|

| Torrefaction Reactor | 0.5 – 2 TPH |

| Pelletizing Section | 500 – 2000 kg/hr |

| Drying System | Customized per input |

Larger or smaller configurations can be built on request.

6. Is it suitable for export markets?

Yes. Fabon’s torrefied pellets meet international quality standards and are suitable for export to Europe, Japan, and Southeast Asia, where demand for carbon-neutral fuel is growing.

7. Does Fabon Engineering provide turnkey solutions?

Yes. Fabon offers complete end-to-end services including:

System design

Fabrication and installation

Operator training

Maintenance and support

Export guidance & carbon credit consultancy

8. What kind of power source is needed to run the plant?

The plant operates on three-phase industrial electricity, with overall power needs depending on capacity. Backup systems like biomass boilers or heat recovery systems can also be integrated.

9. What support is available after installation?

Fabon provides:

On-site commissioning and training

Spare parts and maintenance

Annual Maintenance Contracts (AMC)

Remote diagnostic and technical support

Process optimization consultation