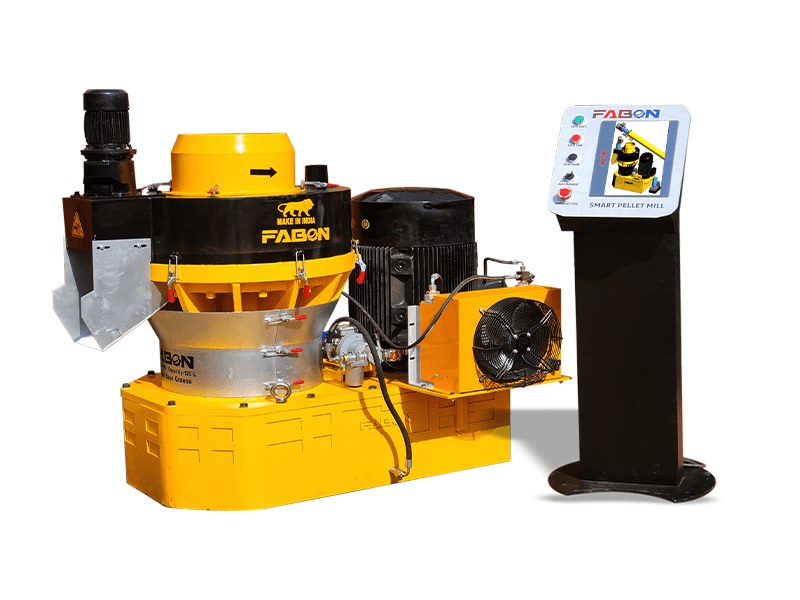

An advanced, fully automated solution for large-scale biomass pellet production. Equipped with a smart operating system, HMI panel, and real-time mobile monitoring, it ensures precision, efficiency, and seamless operation. Designed to process diverse biomass materials into high-quality pellets, it offers process optimization, data analysis, and after-sales service support for sustainable energy and industrial applications.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| RD700 | 700KG/Hour | 150 HP | 15 x 45 x 20 |

| RD1000 | 1000KG/Hour | 204 HP | 15 x 55 x 20 |

| RD2000 | 2000 KG/Hour | 348 HP | 20 x 70 x 25 |

| RD3000 | 3000 KG/Hour | 506 HP | 20 x 90 x 25 |

| RD4000 | 4000 KG/Hour | 670 HP | 20 x 90 x 30 |

| RD5000 | 5000 KG/Hour | 847 HP | 25 x 100 x 30 |

| RD6000 | 6000 KG/Hour | 940 HP | 30 x 100 x 30 |

High-Efficiency Pellet Production for Industrial-Scale Biomass Processing

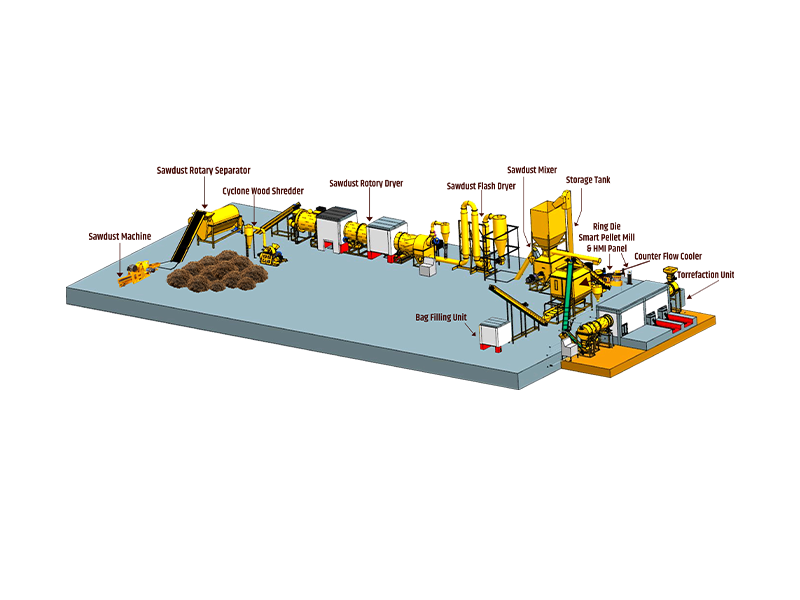

FABON Engineering’s Smart Biomass Pellet Ring Die Plant is an advanced, fully-integrated solution for converting agro-waste, sawdust, wood chips, husk, and other biomass residues into high-density fuel pellets. Engineered with a heavy-duty Ring Die Pellet Mill, this plant ensures high output, uniform pellet quality, and long-term operational stability for commercial biomass energy applications.

✅ Key Features:

High Production Capacity: Available in 1 TPH, 2 TPH, 5 TPH and above

Ring Die Pellet Mill: Suitable for large-scale, continuous operation

Fully Automated System: Integrated with PLC/HMI for smart control

Fuel Flexibility: Handles sawdust, rice husk, wood powder, straw, bagasse & more

Heavy-Duty Components: Built for 24×7 operation with minimal maintenance

Energy Efficient & Eco-Friendly: Low emissions and high thermal conversion rate

🏭 Applications:

Biomass Power Plants

Industrial Boilers

Export-Grade Biomass Fuel Production

Commercial Pellet Manufacturing Units

🔧 Included Systems:

Raw Material Feeder & Crusher

Flash Dryer / Rotary Dryer

Ring Die Pellet Mill

Pellet Cooler & Screener

Packing Machine (Optional)

Centralized Control Panel

🌿 Why Choose FABON:

Proven Design with ISO 9001:2015 Quality Standards

One-Year Warranty & On-Site Commissioning

Spare Parts, Service & AMC Support

Custom Plant Layouts & Turnkey Solutions Available