FABON Flash Dryer: Fast, Efficient Drying Technology for High-Performance Industries

Introduction

In today’s high-speed industrial environment, efficient drying solutions are essential to improve product quality, increase production speed, and reduce operational costs. The FABON Flash Dryer represents the next generation of drying technology, offering rapid moisture removal, minimal thermal degradation, and maximum energy efficiency. Engineered with precision and designed for versatility, this dryer is the ideal solution for processing fine, heat-sensitive, or sticky materials across various industries.

If you’re searching for a reliable, high-capacity, low-energy drying system, the FABON Flash Dryer is your answer. Backed by FABON Engineering’s legacy of innovation and service excellence, this equipment is designed to meet the drying challenges of modern industry.

Table of Contents

What is a Flash Dryer?

About FABON Engineering

Overview of FABON Flash Dryer

Working Principle of the FABON Flash Dryer

Key Features

Technical Specifications

Material Compatibility

Applications Across Industries

Advantages of FABON Flash Dryer

Flash Dryer vs Other Drying Technologies

Energy Efficiency and Sustainability

Customization and Automation

Installation and Commissioning

Maintenance and Support

Compliance and Safety Standards

Customer Testimonials

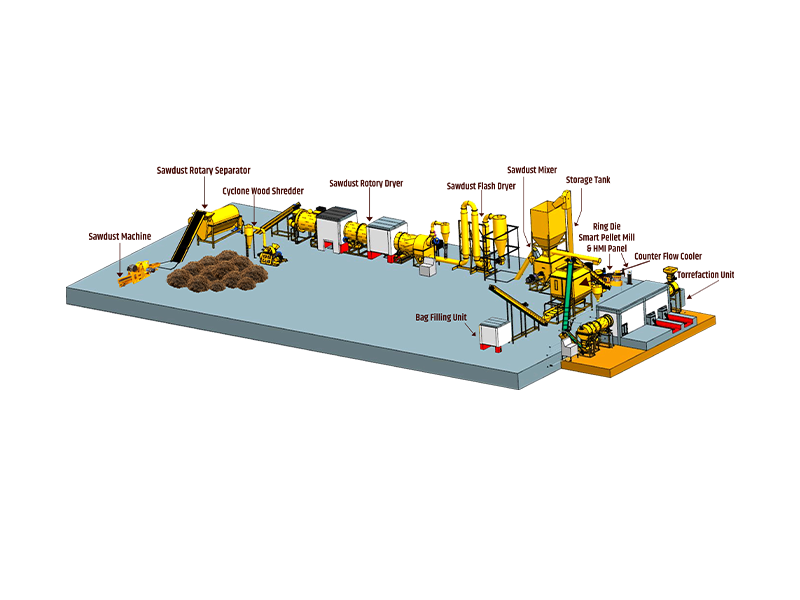

FABON Flash Dryer in Biomass Industry

FAQs

Why Choose FABON?

Contact FABON

What is a Flash Dryer?

A Flash Dryer, also known as a pneumatic dryer, is an industrial drying system used to quickly reduce the moisture content of materials by conveying them through a stream of hot air. The material is suspended in the air stream, allowing for rapid heat transfer and moisture evaporation. Flash dryers are especially suited for drying powders, slurries, and small particulate materials.

About FABON Engineering

FABON Engineering is a trusted Indian manufacturer of biomass machinery and industrial process equipment. With a deep focus on innovation, durability, and energy efficiency, FABON has developed an extensive product line including Rotary Dryers, Hammer Mills, Wood Shredders, Pellet Making Machines, and Flash Dryers.

Our engineering excellence, customization capabilities, and robust service support make us the preferred partner for industries looking to optimize production and reduce operational inefficiencies.

Overview of FABON Flash Dryer

The FABON Flash Dryer is engineered to meet the demanding needs of industries requiring high-speed drying. Designed to handle fine powders, fibrous materials, and wet slurries, this system can reduce moisture content from 35% down to 5-10% in seconds.

Our flash dryers integrate high-temperature air generators, optimized airflow dynamics, and moisture control systems to deliver efficient drying while maintaining product quality.

Working Principle of the FABON Flash Dryer

The flash dryer operates on a simple yet highly effective principle:

Material Feeding: Wet material is fed through a screw or rotary feeder into the hot air stream.

Drying Chamber: As the material is suspended in the hot air, rapid heat transfer causes surface and internal moisture to evaporate.

Air-Material Separation: The air-material mixture passes through a cyclone separator or bag filter, where dry solids are separated.

Exhaust System: Moist air exits through a stack or is treated via a dust collector.

Key Features

Rapid Drying in Seconds

High Temperature Airflow (up to 300°C)

Pneumatic Conveying and Drying in One Step

Stainless Steel Construction Options

Automated Temperature and Moisture Controls

Integrated Cyclone or Bag Filter System

Small Footprint, High Throughput

Fuel Flexibility: Biomass, Gas, or Diesel

Technical Specifications

Model Capacity (TPH) Inlet Moisture (%) Outlet Moisture (%) Power Consumption (kW) Heat Source

FD-500 0.5 – 1.0 25 – 40 5 – 10 15 – 20 Biomass / Gas / Diesel

FD-1000 1.0 – 2.0 25 – 40 5 – 10 20 – 30 Biomass / Gas / Diesel

FD-2000 2.0 – 4.0 25 – 40 5 – 10 30 – 45 Biomass / Gas / Diesel

Note: Custom configurations available upon request

Material Compatibility

FABON Flash Dryers can handle a broad range of raw materials:

Biomass: Sawdust, wood powder, rice husk

Agriculture: Groundnut shell powder, wheat bran

Food: Starch, sugar, yeast, protein extracts

Pharmaceuticals: APIs, herbal extracts

Minerals: Kaolin, clay, silica

Chemicals: Pigments, resins, polymers

Applications Across Industries

Biomass Fuel & Pellet Manufacturing

Agro Waste Processing

Food Ingredients & Nutraceuticals

Starch & Glucose Plants

Pharmaceutical Production

Pigment & Dye Manufacturing

Wastewater Sludge Drying

Mineral and Mining Industry

Advantages of FABON Flash Dryer

Ultra-Fast Drying: Finish drying in under 10 seconds.

Low Capital and Operational Cost: High ROI due to efficient design.

Eco-Friendly Operation: Lower emissions with biomass or gas heat sources.