Biomass Torrefaction Pellet Plant: Revolutionizing Renewable Energy Production

What is a Biomass Torrefaction Pellet Plant?

A Biomass Torrefaction Pellet Plant is an advanced bioenergy production facility designed to convert raw biomass—such as agricultural residues, wood chips, and organic waste—into torrefied biomass pellets. These black pellets are a superior solid biofuel with enhanced energy density, hydrophobic properties, and improved combustion efficiency.

Why Torrefaction?

Torrefaction is a thermal pre-treatment process carried out at 200–300°C in the absence of oxygen. This process removes moisture and volatile components from biomass, resulting in a product that resembles coal in appearance and energy characteristics—without the harmful emissions.

Key Benefits of Torrefied Biomass Pellets:

Higher Energy Density: Torrefied pellets deliver up to 30% more energy than traditional white pellets.

Hydrophobic Nature: Resistant to moisture, making them easier to store and transport.

Uniform Composition: Ideal for co-firing in coal power plants and industrial boilers.

Lower Transportation Costs: Higher energy per ton means more efficient logistics.

Carbon Neutral: Derived from renewable resources with a significantly lower carbon footprint.

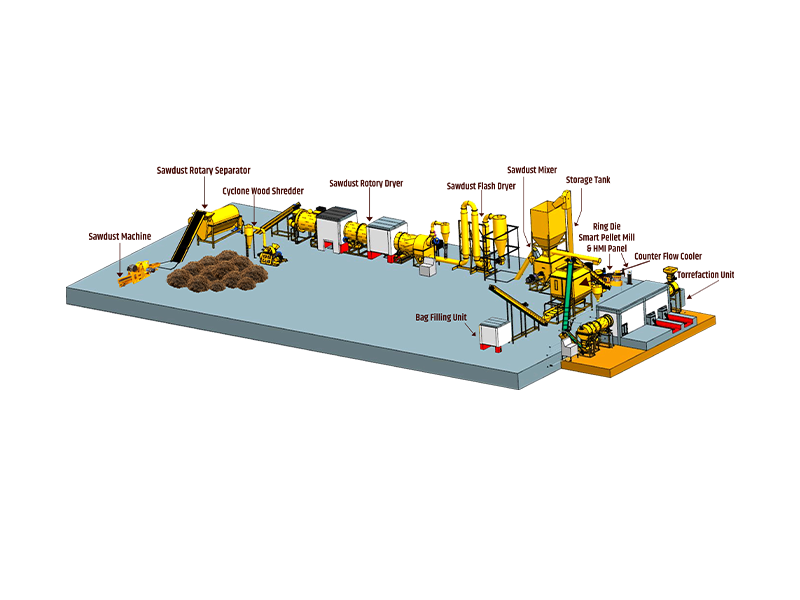

How Does a Biomass Torrefaction Pellet Plant Work?

A typical torrefaction plant includes the following process steps:

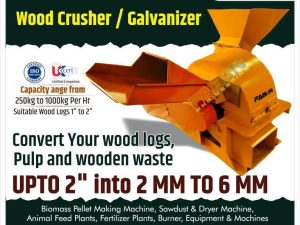

Biomass Pre-treatment

Drying and size reduction (chipping, shredding)

Removal of contaminants

Torrefaction Reactor

Controlled heating in an inert or low-oxygen environment

Volatile gases may be captured for energy recovery

Pelletization

Torrefied biomass is compressed into dense pellets

Cooling and Packaging

Finished pellets are cooled, screened, and bagged or stored in silos

Emission Control Systems

Integrated solutions for capturing and reducing VOCs and particulates

Applications of Torrefied Biomass Pellets

Coal Power Plants: Direct substitution or co-firing with coal

Industrial Heating: Cement, steel, and chemical industries

Residential Heating: Clean-burning fuel for pellet stoves and boilers

Export Markets: High demand in Europe and Asia for sustainable fuel alternatives

Why Invest in a Biomass Torrefaction Pellet Plant?

With rising concerns about climate change and tightening environmental regulations, industries are rapidly shifting toward sustainable energy solutions. Torrefied biomass pellets offer a cost-effective and eco-friendly alternative to fossil fuels. Investing in a biomass torrefaction plant enables:

Energy Security through locally sourced renewable feedstock

Carbon Credits and Incentives in many jurisdictions

Market Differentiation as a green technology leader

Global Export Opportunities in the fast-growing biomass fuel market

Choose the Right Torrefaction Technology Partner

Selecting the right technology and plant partner is crucial. Look for providers with:

Proven engineering expertise

Modular and scalable plant designs

Robust quality control and automation

Full-service support from design to commissioning

Conclusion

A Biomass Torrefaction Pellet Plant is a transformative solution in the renewable energy sector. By turning low-value biomass into high-energy, carbon-neutral fuel, it not only helps reduce reliance on fossil fuels but also contributes to a cleaner, more sustainable future. Whether you’re a utility company, industrial player, or investor, torrefied biomass presents a compelling opportunity.