Category: Biomass Pellet Plant

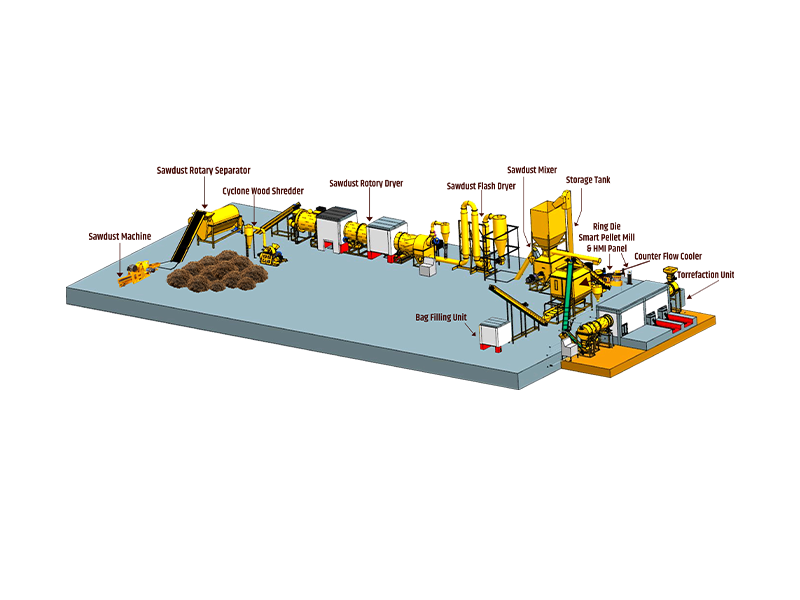

A Biomass Pellet Torrefaction Plant is an advanced facility designed to process biomass into torrefied biomass pellets, which are superior in energy content, durability, and transportability. This plant uses a controlled thermal process called torrefaction, where raw biomass materials such as wood chips, agricultural waste, or forestry residues are heated at temperatures ranging from 200°C to 300°C in the absence of oxygen.

Key Features of a Biomass Pellet Torrefaction Plant:

Applications of Torrefied Biomass Pellets:

Why Choose FABON for Your Biomass Pellet Torrefaction Plant?

An advanced, fully automated solution for large-scale biomass pellet production. Equipped with a smart operating system, HMI panel, and real-time mobile monitoring, it ensures precision, efficiency, and seamless operation. Designed to process diverse biomass materials into high-quality pellets, it offers process optimization, data analysis, and after-sales service support for sustainable energy and industrial applications.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| RD700 | 700KG/Hour | 150 HP | 15 x 45 x 20 |

| RD1000 | 1000KG/Hour | 204 HP | 15 x 55 x 20 |

| RD2000 | 2000 KG/Hour | 348 HP | 20 x 70 x 25 |

| RD3000 | 3000 KG/Hour | 506 HP | 20 x 90 x 25 |

| RD4000 | 4000 KG/Hour | 670 HP | 20 x 90 x 30 |

| RD5000 | 5000 KG/Hour | 847 HP | 25 x 100 x 30 |

| RD6000 | 6000 KG/Hour | 940 HP | 30 x 100 x 30 |

YULONG Biomass Pellet Making Machine – Precision Pelletizing for the Future of Renewable Energy Introduction: Leading the Biomass Revolution with YULONG In the global shift toward sustainable energy, biomass pellet production has become a critical technology for reducing dependence on fossil fuels. As industries, power plants, and heating systems transition toward greener energy, the demand…

Biomass Torrefaction Pellet Plant: Revolutionizing Renewable Energy Production What is a Biomass Torrefaction Pellet Plant? A Biomass Torrefaction Pellet Plant is an advanced bioenergy production facility designed to convert raw biomass—such as agricultural residues, wood chips, and organic waste—into torrefied biomass pellets. These black pellets are a superior solid biofuel with enhanced energy density, hydrophobic…

FABON Biomass Pellet Making Machine: Advanced Solutions for Sustainable Energy Introduction In a world increasingly driven by sustainable energy solutions, the FABON Biomass Pellet Making Machine stands out as a cutting-edge innovation in renewable energy technology. Designed for efficiency, durability, and scalability, this machine is ideal for entrepreneurs, agro-industrial businesses, and renewable energy firms seeking…

Versatile and efficient solution for converting biomass waste into high-quality pellets. Ideal for small-scale production, this machine features a compact design, user-friendly operation, and energy efficiency. It processes materials like sawdust, agricultural residues, and forestry waste into durable biomass pellets, suitable for fuel or animal feed. Perfect for eco-friendly operations and sustainable energy solutions.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| BM250 | 250KG/Hour | 55 HP | 30 x 45 x 20 |

| BM500 | 500KG/Hour | 80 HP | 40 x 50 x 20 |

| BM1000 | 1000 KG/Hour | 145 HP | 40 x 60 x 25 |

WhatsApp us