FABON Biomass Pellet Making Machine: Advanced Solutions for Sustainable Energy

Introduction

In a world increasingly driven by sustainable energy solutions, the FABON Biomass Pellet Making Machine stands out as a cutting-edge innovation in renewable energy technology. Designed for efficiency, durability, and scalability, this machine is ideal for entrepreneurs, agro-industrial businesses, and renewable energy firms seeking to convert organic waste into high-density, eco-friendly biomass pellets.

FABON Engineering brings decades of industrial experience to biomass processing, and our pellet machines are manufactured with precision engineering and robust materials to ensure long-lasting performance. Whether you’re producing fuel for boilers, gasifiers, or selling commercial biomass pellets, the FABON Biomass Pellet Machine is your reliable partner in the green energy revolution.

1. What is a Biomass Pellet Making Machine?

A biomass pellet making machine compresses raw materials like sawdust, agricultural residues, forestry waste, and organic matter into uniform cylindrical biomass pellets. These pellets serve as a clean, renewable fuel source, replacing coal, LPG, and diesel in industrial applications.

2. FABON’s Role in Biomass Pelletization

FABON Engineering is a recognized leader in manufacturing high-efficiency biomass machinery. Our pellet machines are custom-built for Indian and global conditions, engineered for high throughput, minimal downtime, and superior pellet quality. Our in-house R&D team continuously upgrades technology to meet evolving energy demands and sustainability goals.

3. Technical Specifications

Feature Specification

Model FABON-BP1000, BP2000, BP3000

Capacity 1 TPH, 2 TPH, 3 TPH

Die Type Ring Die (Alloy Steel, heat-treated)

Motor Power 75 HP to 200 HP

Pellet Diameter 6 mm / 8 mm / 10 mm

Drive System Gear Drive / Belt Drive (Customizable)

Control Panel Digital PLC-Based

Feeder System Variable Speed Screw Feeder

Cooling System Integrated Air Cooling

Lubrication Automatic Greasing System

Automation Level Semi & Fully Automatic

Safety Features Overload Protection, Emergency Stop, Interlock System

Custom configurations available based on production needs.

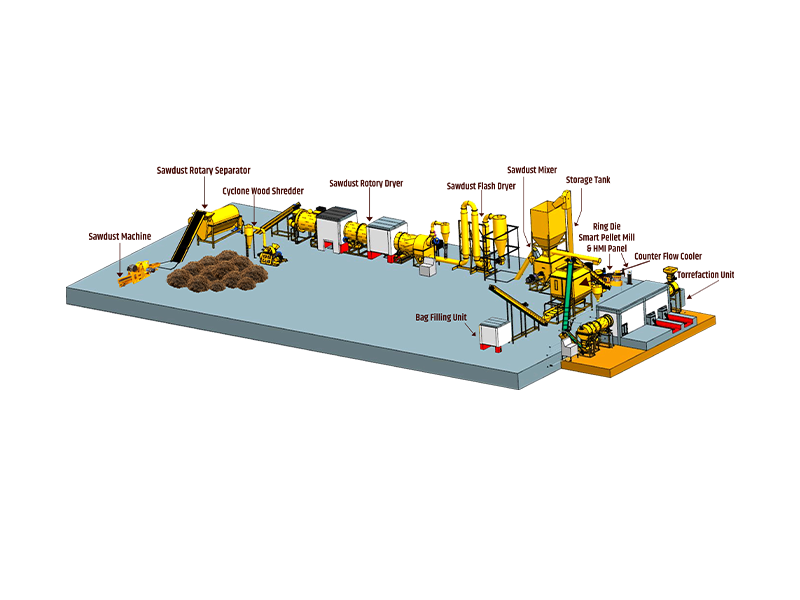

4. How It Works: Pelletization Process

Raw Material Feeding: Preprocessed raw materials (sawdust, husk, etc.) are fed into the hopper.

Conditioning: Moisture content is adjusted using a rotary or flash dryer.

Pelletizing: Material is compressed through a ring die by rotating rollers to form dense pellets.

Cooling: Pellets are cooled using an air-cooling system to maintain structure and durability.

5. Raw Materials Suitable for FABON Pellet Machine

Sawdust

Groundnut Shell

Rice Husk

Corn Stalk

Cotton Stalk

Wheat Straw

Coconut Shell Powder

Bagasse

Forestry Waste

Wood Chips (after shredding)

Moisture content should be between 10% – 15% for optimal pelletizing.

6. Output Quality & Pellet Standards

FABON pellet machines ensure:

High Density (1.1–1.4 g/cm³)

Low Ash Content (< 2%)

Uniform Size

High GCV (3500–4500 kcal/kg)

Minimal Fines

Meets international standards like ENplus and IS standards for biomass fuel.

7. Applications of Biomass Pellets

Industrial Boilers

Thermal Power Plants

Commercial Cooking Systems

Gasifiers

Pellet-Based Heating Systems

Export to European and Middle Eastern Markets

8. Advantages of Using FABON Pellet Machine

Energy Efficient: Lower operational cost

Heavy-Duty Design: Long service life with minimal wear

Automation Ready: Digital interface and auto-lubrication

Custom Engineering: Machines suited to your raw material

Local Support: Indian spares availability and PAN India service

Eco-Friendly: Reduces carbon footprint and fossil fuel use

10. Why Choose FABON Over Competitors?

Feature FABON Others (General)

Indian Manufacturing Yes Mostly Imported

Custom Design Yes Limited Options

After-Sales Support Strong Network Often Delayed

Spare Parts In-stock Lead Time 30+ Days

Pricing Competitive High Import Duties

R&D Capabilities In-house Generic Tech

11. Installation, Operation, and Maintenance Guide

Installation:

Site visit by FABON technician

Foundation layout and power setup assistance

Trial run and operator training

Operation:

Simple touchscreen PLC control

Adjustable parameters for feed type

Real-time performance monitoring

Maintenance:

Daily greasing (auto option available)

Replace die/roller after 700–800 hrs

Free AMC for first 6 months*

12. Government Policies and Subsidies (India – 2025 Update)

Biomass pelletization is now a priority sector under India’s renewable energy initiatives.

MNRE Subsidy: Up to 35% capital subsidy for pellet plant setup

State-Specific Grants: Additional incentives in Punjab, Haryana, Maharashtra

GST Benefits: Machinery taxed at concessional rates (18%)

Carbon Credits: Eligibility under clean development mechanisms (CDM)

For subsidy consultation, contact FABON support.