Biomass Flat Die Pellet Plant – Compact, Cost-Effective Pelletizing for Small to Medium Scale Production

What is a Biomass Flat Die Pellet Plant?

A Biomass Flat Die Pellet Plant is a compact and efficient solution for converting various types of biomass—such as sawdust, rice husk, straw, coconut shell, and agricultural residues—into solid biofuel pellets. Using a flat die pellet mill, this plant is ideal for small to medium-scale biomass pellet production, offering excellent flexibility, lower investment cost, and ease of operation.

Whether you’re a startup in bioenergy, a farm looking for waste valorization, or a small manufacturer wanting to reduce fuel costs, a flat die pellet plant provides a smart entry into the world of biomass energy.

How Flat Die Pellet Plants Work

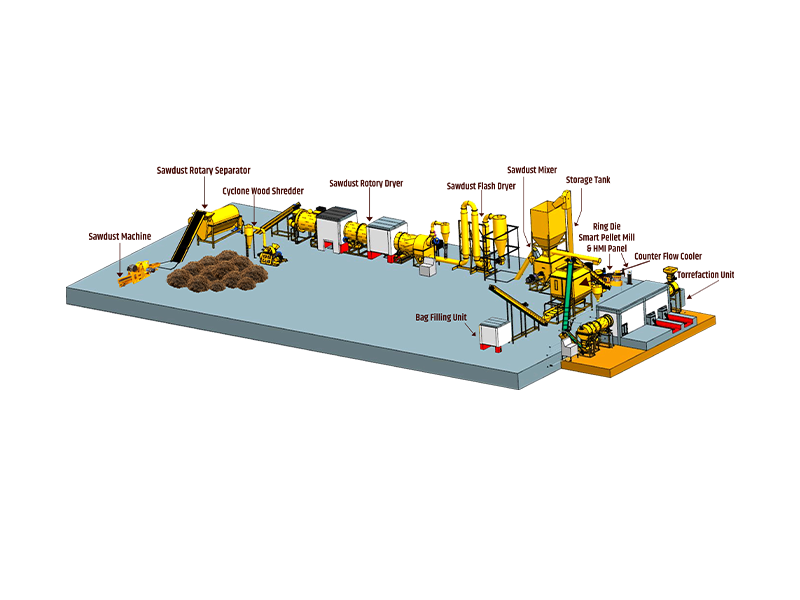

The core of this system is the flat die pellet mill, which compresses finely ground biomass under high pressure through a flat die to form dense cylindrical pellets. The process typically includes:

Biomass Crushing

Pre-treatment includes shredding or grinding raw materials to suitable sizes.

Drying System

Ensures optimal moisture content (usually 10-15%) for pelletizing.

Pelletizing with Flat Die Mill

The flat die and roller compress the material into uniform pellets.

Cooling & Screening

Pellets are cooled and filtered for consistent quality.

Packaging or Bulk Storage

Ready-to-use biomass fuel for domestic or commercial use.

Advantages of Flat Die Pellet Plants

✅ Low Capital Investment

Flat die systems are more affordable than ring die counterparts, making them perfect for small-scale applications.

✅ Simple Operation & Maintenance

Minimal training is required for operators, and the machine parts are easy to replace and service.

✅ Versatile Feedstock Compatibility

Can process a wide range of biomass types—wood chips, crop waste, peanut shells, and more.

✅ Compact Footprint

Requires less space, making it ideal for rural setups or mobile pelletizing units.

✅ Suitable for Custom Pellet Sizes

Adjustable dies can produce pellets in various diameters (usually 6–10 mm), depending on end use.

Applications of Biomass Flat Die Pellet Plants

Rural & Agricultural Use

Convert farm waste into renewable fuel or additional income.

Small Industrial Heating

Fuel biomass boilers or furnaces for local heating or process energy.

Residential Heating

Supply biomass pellets for domestic pellet stoves.

Startups in Renewable Energy

Ideal entry-level system for those entering the biofuel sector.

Animal Feed Production (with minor modifications)

Can also be adapted for pressing feed pellets in the livestock sector.

Why Choose a Flat Die Pellet Plant for Your Business?

In a time where energy cost reduction, carbon footprint minimization, and resource efficiency are critical, a biomass flat die pellet plant is a smart investment. It allows you to:

Utilize locally available biomass waste

Produce fuel for self-use or commercial sale

Enter the growing bioenergy market with low risk

Comply with environmental regulations on waste management and emissions

FABON Engineering – Reliable Flat Die Pellet Plant Manufacturer

At FABON Engineering, we specialize in customized biomass pellet plant solutions tailored to your capacity, feedstock, and budget. Our flat die pellet plants are built for durability, efficiency, and high return on investment. We offer:

Turnkey plant solutions

Expert technical support

High-performance pellet mills with premium die and roller materials

End-to-end services including installation, training, and after-sales support.