Poultry Feed Machine – Complete Guide to Equipment, Ingredients, Cost, and Profitability.

Introduction

Poultry farming is one of the fastest-growing agricultural sectors worldwide, and feed quality directly impacts bird growth, egg production, and farm profitability. With rising demand for fresh and hygienic feed, many poultry farmers and entrepreneurs are setting up poultry feed plants to produce their own feed instead of relying on the market.

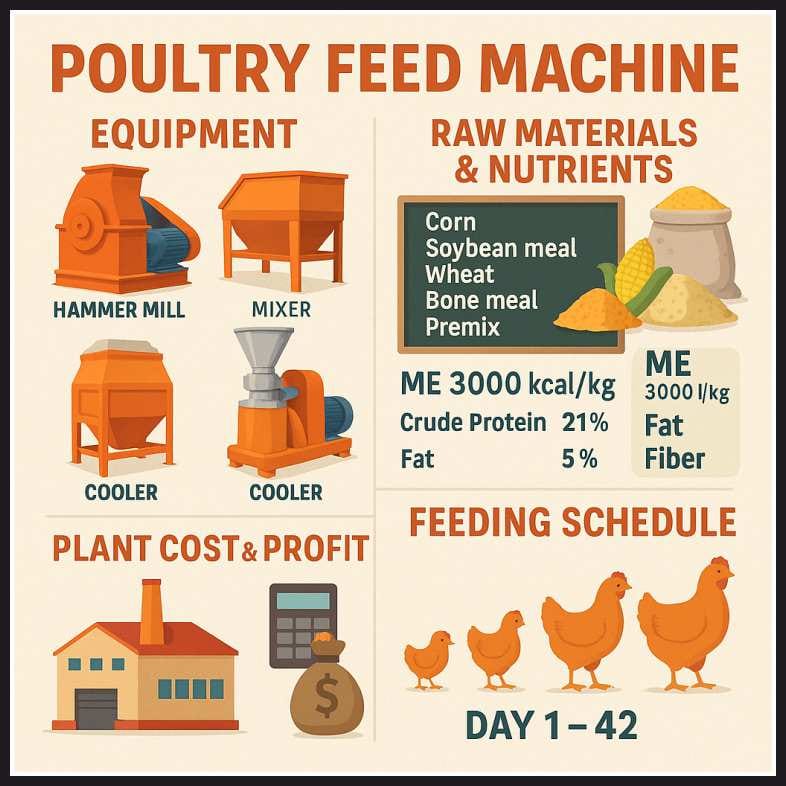

A poultry feed machine converts raw materials into balanced, digestible, and uniform feed pellets or mash for broilers, layers, and breeders. In this blog, we will cover types of machines, ingredients, formulations, plant cost, ROI, and profit potential.

1. Types of Poultry Feed Machines

A poultry feed production line generally consists of several machines working in sequence:

1.1 Feed Grinder (Hammer Mill)

- Purpose: Grinds raw materials such as maize, wheat, soybean, and rice bran into fine powder.

- Capacity: 500 kg/hr to 10 TPH.

- Power Requirement: 7.5 HP to 75 HP.

- Note: Finer grinding improves digestibility.

1.2 Feed Mixer

- Purpose: Mixes ground materials uniformly with vitamins, minerals, and additives.

- Types: Ribbon Mixer, Paddle Mixer, or Double Shaft Mixer.

- Capacity: 250 kg/batch to 5 ton/batch.

1.3 Pellet Mill

- Purpose: Compresses mixed feed into uniform pellets for easier consumption and less wastage.

- Types:

- Flat Die Pellet Mill – Best for small/medium-scale production.

- Ring Die Pellet Mill – Ideal for high-volume commercial plants.

- Power Requirement: 20 HP to 150 HP.

1.4 Cooler

- Purpose: Reduces the temperature and moisture of freshly made pellets to prevent spoilage.

1.5 Crumbler

- Purpose: Breaks large pellets into crumbles for chicks.

1.6 Automatic Bagging Machine

- Purpose: Packs feed into 25–50 kg bags for storage and sale.

2. Raw Materials and Ingredients

Poultry feed is a mix of energy sources, protein-rich ingredients, and essential vitamins and minerals.

| Raw Material | Protein (%) | Fat (%) | Fiber (%) |

| Maize/Corn | 8–9 | 3.5 | 2.0 |

| Soybean Meal | 44–48 | 1.0 | 6.0 |

| Rice Bran | 13–15 | 15–18 | 7.0 |

| Wheat Bran | 15–16 | 4.0 | 8.0 |

| Fish Meal | 50–55 | 8.0 | 1.0 |

| Sunflower Cake | 28–32 | 1.5 | 18.0 |

| Vitamins & Minerals | – | – | – |

3. Sample Poultry Feed Formulations

Broiler Starter Feed (0–3 weeks)

- Maize: 55%

- Soybean Meal: 30%

- Fish Meal: 5%

- Rice Bran: 5%

- Vegetable Oil: 2%

- Vitamins & Minerals: 3%

Layer Grower Feed

- Maize: 50%

- Soybean Meal: 25%

- Wheat Bran: 15%

- Sunflower Cake: 5%

- Vegetable Oil: 2%

- Vitamins & Minerals: 3%

Formulations can be adjusted based on bird type, age, and local ingredient availability.

4. Plant Setup and Machinery Costing

| Plant Capacity | Estimated Cost (INR) | Included Machinery |

| 500 kg/hr | ₹8–12 Lakhs | Grinder, Mixer, Pellet Mill, Cooler, Crumbler |

| 1 TPH | ₹18–25 Lakhs | Full Line with Bagging System |

| 2 TPH | ₹30–45 Lakhs | Heavy-duty, Fully Automated |

| 5 TPH | ₹70 Lakhs – ₹1.2 Cr | Industrial Ring Die Plant |

5. Operating Cost & ROI

5.1 Operating Costs

- Raw Materials: 70–75% of total cost.

- Electricity: ₹3–5/unit (20–100 HP total load).

- Labor: 4–8 workers for small plants; 10–15 for large.

- Maintenance: 3–5% of machine cost annually.

5.2 ROI & Profitability Example (1 TPH Plant)

- Daily Production: 8 tons/day (1 ton/hour × 8 hours).

- Production Cost: ₹25–28/kg.

- Selling Price: ₹32–36/kg.

- Profit per Ton: ₹7–8.

- Daily Profit: ₹56,000–₹64,000.

- Monthly Profit (26 days): ₹14–16 Lakhs.

- ROI Period: 5–8 months.

6. Benefits of Having Your Own Poultry Feed Machine

- Quality Control: Make feed tailored to your flock’s needs.

- Cost Efficiency: Avoid high market feed prices.

- Freshness: Produce on demand, ensuring freshness.

- Customization: Adjust formulas for different bird types and ages.

- Business Opportunity: Sell surplus feed to other poultry farms.

7. Poultry Feed Schedule – From Day 1 to Maturity

4.1 Broiler Chicken Feed Schedule

| Age (Days) | Feed Type | Feeding Frequency | Avg. Feed Intake per Bird/day | Key Nutritional Focus |

| 0–10 | Broiler Starter (crumbles) | 4–5 times/day | 15–25 g | High protein (21–23%), immunity boosters, vitamins |

| 11–24 | Broiler Grower (pellets/crumbles) | 3–4 times/day | 50–80 g | Balanced protein (19–21%), energy for rapid growth |

| 25–35 | Broiler Finisher (pellets) | 3 times/day | 100–150 g | High energy, moderate protein (18–19%), weight gain focus |

💡 Tip: Ensure clean water is always available; adjust feed intake based on bird weight and climate.

4.2 Layer Chicken Feed Schedule

| Age (Weeks) | Feed Type | Feeding Frequency | Avg. Feed Intake per Bird/day | Key Nutritional Focus |

| 0–6 | Chick Starter (crumbles) | 4–5 times/day | 10–30 g | High protein (20–22%) for skeletal and feather growth |

| 7–15 | Grower Feed (pellets/mash) | 3–4 times/day | 40–70 g | Protein (16–18%) and balanced minerals for body development |

| 16–20 | Pre-Layer Feed (pellets/mash) | 3 times/day | 80–90 g | Protein (16–18%) with added calcium for bone strength |

| 21+ | Layer Feed (pellets/mash) | 2–3 times/day | 100–120 g | Protein (16–18%) and high calcium (3–4%) for egg production |

💡 Tip: For layers, calcium supplementation (limestone, oyster shell) is critical from pre-laying stage onwards.

8. Plant Setup and Machinery Costing

(As given earlier — 500 kg/hr plant ₹8–12 Lakhs, 1 TPH ₹18–25 Lakhs, etc.)

9. Operating Cost & ROI

(As given earlier — 1 TPH plant profit ₹14–16 Lakhs/month with 5–8 month ROI)

10. Benefits of In-House Poultry Feed Production

- Consistent quality

- Fresh production

- Cost control

- Customizable formulations

- Extra income from selling surplus feed

Conclusion

A poultry feed plant is a profitable investment for farmers and agri-entrepreneurs. With the right combination of machines, quality raw materials, and proper formulations, you can ensure healthier birds, better production, and high profits.

FABON Engineering Pvt Ltd offers customized poultry feed plant solutions from 500 kg/hr to 5 TPH, complete with installation, 1-year warranty, and after-sales service.