Convert Diesel, LDO & LPG Boilers to Biomass Pellets and Cut Fuel Costs by 60%

Switch to Savings: Converting Diesel, LDO & LPG Boilers to Biomass Pellet Fuel

Keywords: boiler conversion to biomass pellets, replace diesel boiler with biomass, biomass pellet boiler retrofit, LDO to biomass boiler conversion, LPG boiler fuel switch, biomass fuel savings

Introduction

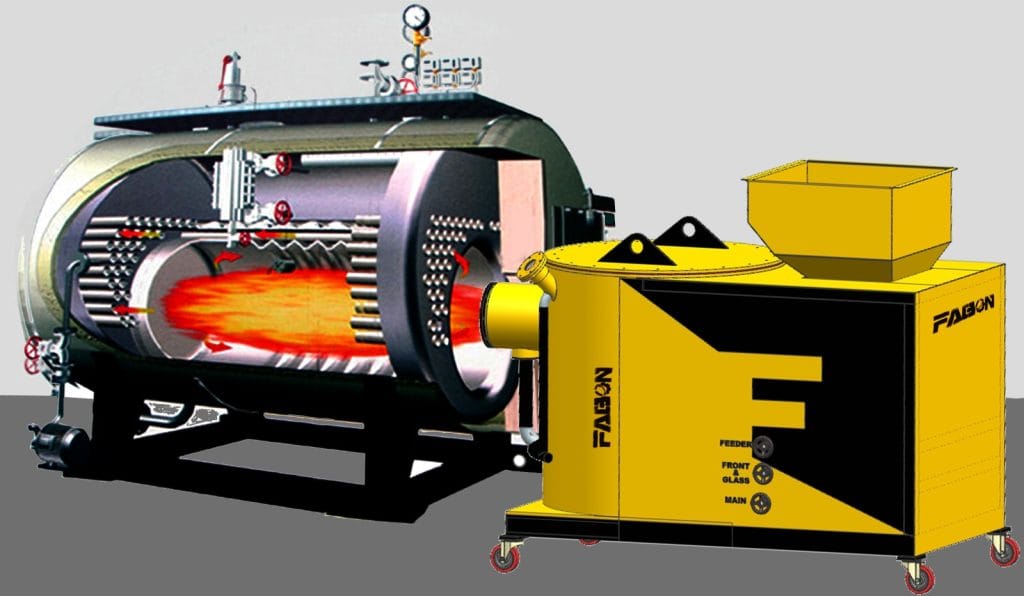

Rising fossil fuel prices and strict environmental regulations are pushing industries to look for cleaner, cost-effective energy alternatives. Converting diesel, LDO, or LPG-fired boilers to biomass pellets is emerging as a practical and profitable solution. At FABON Engineering, we specialize in turnkey biomass conversion solutions that help industries cut fuel costs and reduce carbon emissions—without replacing their existing boilers.

Why Convert to Biomass Pellet Fuel?

Here’s why industries across food processing, pharmaceuticals, textiles, and chemicals are switching:

- 💸 Up to 60% Fuel Cost Reduction: Biomass pellets are significantly cheaper than diesel or LPG.

- 🌱 Eco-Friendly Fuel: Pellets emit fewer greenhouse gases and are carbon-neutral.

- 🔧 Quick Payback: Most clients recover conversion investment in under 12 months.

- 📜 Compliance Ready: Supports environmental certifications and emission norms.

What is Boiler Conversion?

Boiler conversion involves modifying your existing oil or gas-fired boiler to burn biomass pellets as fuel. This includes installing a biomass pellet burner, fuel feeding system, storage hopper, and control unit.

FABON Engineering offers:

- ✅ Customized retrofitting for 200 kg/hr to 5 TPH boilers

- ✅ Pellet burners with high combustion efficiency (90%+)

- ✅ Automated feeding & ash removal systems

- ✅ Control panels with temperature & flame sensors

Technical Feasibility

Whether you’re running:

- 🛢️ Diesel-fired thermic fluid heaters

- 🧪 LDO-fired steam boilers

- 🔥 LPG-based hot water generators

We retrofit them with minimal changes to the main boiler body. FABON ensures:

- 🔄 Seamless integration

- 🛠️ Minimal downtime

- 🔥 Stable combustion with pellet fuel

- 🌡️ Precise temperature control

Who Can Benefit?

Industries using thermal energy for process heating, drying, steaming, or sterilizing can benefit immensely:

- Food & Beverage: Breweries, dairy, bakeries, snacks

- Pharma & Cosmetics: Sterilizers, reactors

- Textile & Garment: Dyeing, ironing, washing

- Paper & Packaging: Drying, corrugation

- Hotels & Hospitals: Hot water and steam boilers

Key Benefits of Biomass Conversion

| Feature | Diesel/LDO/LPG | Biomass Pellets |

|---|---|---|

| Fuel Cost | High | Low (₹5–8/kg) |

| Emissions | High CO₂ & NOx | Low & Carbon-neutral |

| Safety | Explosive | Safer & Stable |

| Automation | Manual or Semi | Fully Automatic |

| Fuel Source | Imported | Locally Available |

Why FABON Engineering?

As a trusted name in biomass energy systems, FABON Engineering offers:

- 🔧 End-to-End Conversion Services

- 📐 Custom Engineering & Burner Sizing

- 🧪 Fuel Testing & Feasibility Reports

- 🛠️ On-Site Installation & Support

- 🔄 After-sales Maintenance Contracts

Our systems are already deployed across India, Southeast Asia, and Africa, with measurable savings and performance reliability.

Real-World ROI: A Case Example

Textile Unit, Gujarat

- 🔥 Existing System: 2 TPH Diesel Boiler

- 🔁 Converted: Biomass Pellet Burner

- 💰 Fuel Cost Reduced: From ₹23/kg (diesel) to ₹7/kg (pellets)

- ⏱ Payback Time: 7 months

- 🌍 CO₂ Savings: ~30 tons/month