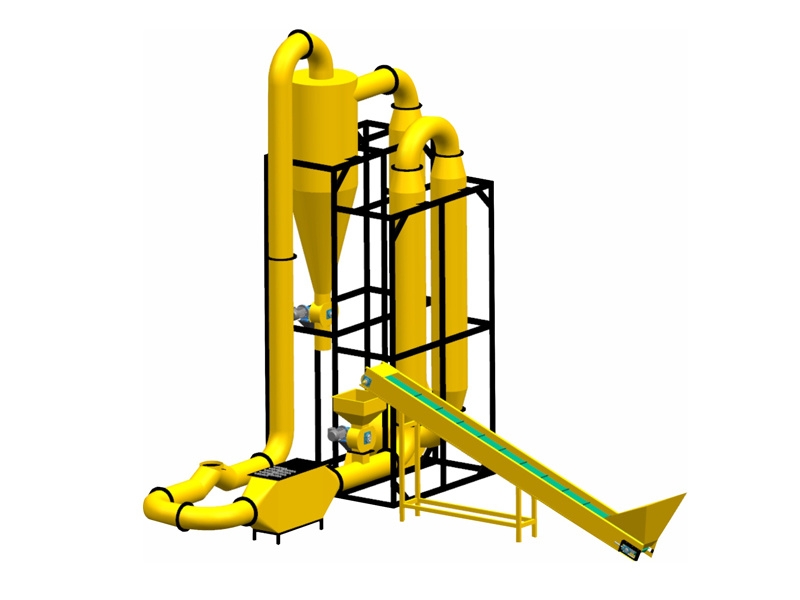

Biomass Sawdust Flash Dryer

The Flash Dryer by FABON Engineering Pvt. Ltd. is a state-of-the-art drying system designed to reduce moisture content in biomass materials quickly and efficiently. Ideal for industries involved in biomass pellet production, this dryer ensures consistent quality and high productivity.

The Sawdust Dryer by FABON Engineering Pvt. Ltd. is a cutting-edge flash drying system designed to optimize moisture reduction in biomass materials. Engineered for efficiency and speed, this innovative dryer is the perfect solution for industries involved in biomass pellet production, offering consistent quality and unmatched productivity. Whether it’s sawdust, wood chips, or agricultural residues, this Sawdust Dryer ensures high-quality output suitable for fuel, pellet production, and other industrial applications.

What sets the Sawdust Dryer apart is its ability to handle large volumes of material while maintaining uniform moisture reduction. By employing flash drying technology, it rapidly heats and dries biomass, significantly reducing processing time compared to traditional drying methods. This not only enhances productivity but also ensures that the material retains its quality and structure throughout the process.

Key Features of the Sawdust Dryer

- 1. High Efficiency: The flash drying technology allows for rapid drying, ensuring minimal energy consumption while delivering consistent results.

- 2. Versatility: Designed to handle various biomass materials, including sawdust, wood chips, and agricultural residues.

- 3. Compact Design: Its space-saving design makes it an ideal choice for industries with limited operational space.

- 4. Energy-Saving Operation: Reduces energy usage, leading to cost savings and environmental benefits.

- 5. Advanced Controls: Equipped with user-friendly controls for precise temperature and moisture level monitoring.

- 6. Durable Construction: Built with high-quality materials to ensure longevity and reliability in demanding industrial environments.

With FABON’s Sawdust Dryer, businesses can achieve superior drying performance, reduce operational costs, and support eco-friendly practices. Whether you’re producing biomass pellets or other materials, this efficient dryer is your trusted partner for high-quality results. Trust FABON Engineering Pvt. Ltd. to deliver innovative solutions for all your biomass drying needs.

| Model | Capacity | Motor |

|---|---|---|

| DR050 | 500 Kg / Hour | 15 HP |

| DR100 | 1 TPH | 20 HP |

| DR200 | 2 TPH | 30 HP |

Rapid Drying Redefined: Biomass Sawdust Flash Dryer by Fabon Engineering, Nashik

In today’s biomass industry, moisture control is a critical step in ensuring efficient fuel processing and high-quality pellet or briquette production. Recognizing the need for rapid, energy-efficient drying systems, Fabon Engineering, based in Nashik, Maharashtra, presents its cutting-edge Biomass Sawdust Flash Dryer — a compact, high-speed drying solution designed for fine biomass materials like sawdust, rice husk, and bagasse.

Introducing the Biomass Sawdust Flash Dryer

The Flash Dryer works on the principle of direct contact drying, where finely divided biomass particles are suspended in a hot air stream. Due to their high surface area and low moisture-holding capacity, materials like sawdust dry almost instantly, making flash drying one of the most efficient methods for rapid moisture removal.

Key Features and Benefits

Ultra-Fast Drying: Dries fine biomass materials in seconds, reducing moisture content from 30–50% to below 12%.

Energy Efficient: Minimal heat loss and optimized airflow result in low energy consumption per kilogram of output.

Compact Design: Requires less floor space than rotary dryers; ideal for operations with space constraints.

Low Maintenance: Simple construction with fewer moving parts ensures easy operation and reduced downtime.

Consistent Output Quality: Delivers uniformly dried material ideal for pelletization, briquetting, and combustion.

Versatile Fuel Options: Operates with biomass burners, steam, oil, or gas-based heating systems.

Applications

The Biomass Sawdust Flash Dryer is ideally suited for:

Biomass pellet and briquette production plants

Wood and agro-waste processing units

Feedstock drying for bioenergy and gasification systems

Pre-treatment for composting and fertilizer plants

Why Choose Fabon Engineering?

✅ Customized Drying Solutions

✅ Turnkey Project Execution

✅ Expert Technical Support

✅ Reliable After-Sales Service & Spare Parts

✅ Proven Field Performance Across India and Abroad

FAQ – Biomass Sawdust Flash Dryer

1. What is a Biomass Sawdust Flash Dryer?

A Flash Dryer is a rapid drying system that uses high-velocity hot air to dry fine biomass materials like sawdust, rice husk, and bagasse. The material is suspended in a drying air stream, enabling moisture evaporation in just a few seconds.

2. What types of biomass materials can be dried?

The Flash Dryer is ideal for fine, low-density, and moisture-rich biomass such as:

Sawdust

Rice husk

Bagasse

Bamboo dust

Coconut husk powder

Pulverized wood waste

Other finely ground agro-residues

3. How fast is the drying process?

The drying time is extremely short — typically 1 to 5 seconds, thanks to the high surface-area exposure of the biomass particles to hot air.

4. What is the moisture reduction capability?

The Flash Dryer typically reduces input moisture from 30–50% down to 8–12%, depending on the initial material and air temperature.

5. What is the capacity range offered by Fabon Engineering?

Fabon Engineering offers customized dryers with capacities ranging from 300 kg/hr to 2 tons/hr, based on client requirements.

6. What are the power and fuel requirements?

Fuel options include:

Biomass (wood chips, briquettes)

Diesel or furnace oil

Natural gas or LPG

Steam (indirect heating option)

Power consumption depends on blower size and system capacity, and a technical proposal is shared after assessing your input conditions.

7. What are the advantages of using a Flash Dryer over a Rotary Dryer?

Faster drying for fine materials

Smaller footprint (compact design)

Lower residence time, minimizing thermal degradation

Efficient moisture removal with lower fuel cost per kg dried

Less mechanical wear due to fewer moving parts

8. Is the dryer fully automated?

Automation options are available, including PLC-based control panels for temperature, airflow, and moisture monitoring.

9. What maintenance is required?

The system is designed for low maintenance, with easy access for cleaning and minimal moving components. Routine inspections of blowers, ducts, and burners are recommended.

10. Can the dryer be integrated with an existing pellet or briquette plant?

Yes, the dryer is modular and easy to integrate into existing biomass processing lines, especially before pellet mills or briquetting machines.

11. Does Fabon Engineering offer installation and training?

Yes, we provide complete turnkey services including design, manufacturing, installation, commissioning, and operator training.

12. How do I get a price quote or technical specification?

To receive a customized quote, contact Fabon Engineering with the following:

Type of biomass

Input & target moisture levels

Required capacity

Preferred fuel source

Space constraints (if any)