BIOMASS PELLET MACHINE PRICE IN INDIA

A Complete Guide for 2 TPH Plant (2025)

The demand for eco-friendly fuel alternatives is booming, and biomass pellets are at the heart of this energy transition. If you’re planning to invest in a 2 Ton Per Hour (TPH) biomass pellet plant, understanding the price, plant size, shed requirements, government subsidies, and return on investment (ROI) is crucial.

This detailed 2025 guide by FABON Engineering covers everything you need to know about setting up a 2 TPH biomass pellet machine in India.

What is a 2 TPH Biomass Pellet Plant?

A 2 TPH biomass pellet plant produces 2 tons of biomass pellets per hour, translating to about 48 tons per day (24-hour shift) and over 14,000 tons annually at full capacity. These pellets are used as fuel in:

- Industrial steam boilers

- Thermal power plants

- Gasifier systems

- Export-grade biomass fuel

Biomass Pellet Machine Price in India for 2 TPH Plant (2025)

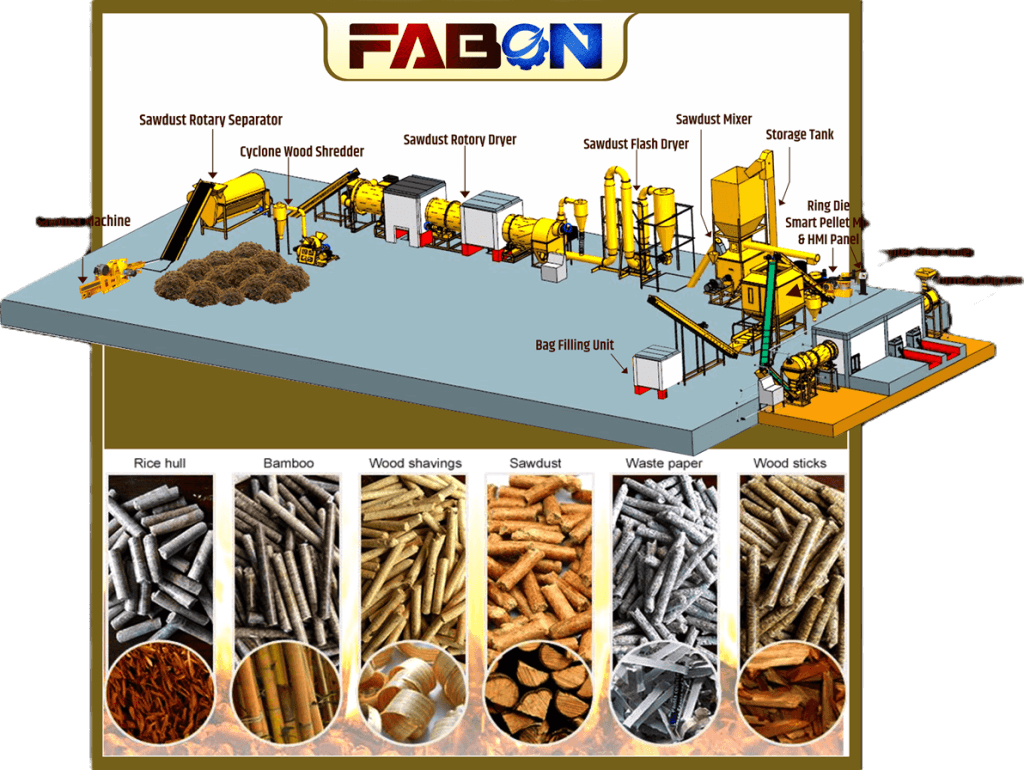

The core component of the plant is the 2 TPH Ring Die Pellet Machine. The total cost depends on various elements like build quality, automation, and supporting equipment.

Price Breakdown (Indicative)

| Equipment | Estimated Cost (INR) |

| 2 TPH Ring Die Pellet Machine | ₹28 – ₹38 Lakh |

| Hammer Mill (Pre-grinder) | ₹4 – ₹6 Lakh |

| Rotary Dryer (2 TPH) | ₹18 – ₹30 Lakh |

| Pellet Cooler & Cyclone System | ₹6 – ₹10 Lakh |

| Dust Collector & Bag Filter | ₹3 – ₹5 Lakh |

| Material Handling Conveyors | ₹5 – ₹8 Lakh |

| Control Panel + Wiring | ₹3 – ₹5 Lakh |

| Installation, Transport, Testing | ₹5 – ₹8 Lakh |

| Total Cost Estimate | ₹72 – ₹1.10 Crore |

👉 Prices may vary based on design, automation, and brand.

Plant & Shed Size for 2 TPH Pellet Plant

To install and operate a 2 TPH pellet plant efficiently, you need adequate land area and shed space.

📏 Land and Shed Requirements

| Component | Requirement |

| Total Land Area | Minimum 40,000–50,000 sq. ft. |

| Covered Shed Area | 18,000–22,000 sq. ft. |

| Shed Height | 22–25 ft |

| Raw Material Storage Area | 12,000–15,000 sq. ft. |

| Finished Pellet Storage | 4,000–6,000 sq. ft. |

| Dryer & Chimney Setup | Open section with 40 ft height |

💡 Civil flooring should be RCC/CC with proper drainage and ventilation.

Electrical and Utility Requirements

| Utility | Specification |

| Total Power Load | 150–180 HP |

| Power Source | 3-Phase, 440V |

| Water Requirement | 500–1000 L/day (for cooling & cleaning) |

| DG Set Backup (Optional) | 125–150 kVA |

Suitable Raw Materials for 2 TPH Pellet Plant

Common raw materials:

- Paddy straw

- Sawdust

- Bagasse

- Cotton stalks

- Groundnut shells

- Wheat husk

- Bamboo dust

Moisture Target:

12–15% (Dryer required for high-moisture materials)

Government Subsidies in 2025

The Indian government, through MNRE, MoAFW, and state nodal agencies, offers capital and interest subsidies for biomass projects.

Subsidy Schemes:

- MNRE – Biomass Pelletization Support

- Capital Subsidy: 15%–35% for machinery cost

- MSMEs get preference

- Agro Waste to Energy Scheme (Ministry of Agriculture)

- Machinery subsidy for paddy straw-based units in Punjab, Haryana, UP, MP, and Chhattisgarh

- State-Level Subsidies

- Offered in states like Maharashtra, Gujarat, Punjab, Tamil Nadu

- Interest Subsidy / Soft Loans

- Available through SIDBI, NABARD, and cooperative banks

📞 FABON assists with complete documentation and subsidy application support.

Return on Investment (ROI) for 2 TPH Pellet Plant

Daily Output:

- 2 TPH x 20 hours = 40 tons/day

- Monthly (25 days): 1000 tons

Financials:

| Component | Value (Approx.) |

| Selling Price (Domestic) | ₹10 – ₹13/kg |

| Monthly Revenue | ₹1.0 – ₹1.3 Crore |

| Raw Material Cost | ₹40 – ₹50 lakh/month |

| Power + Manpower | ₹8 – ₹10 lakh/month |

| Maintenance + Misc | ₹2 – ₹4 lakh/month |

| Net Profit | ₹30 – ₹45 lakh/month |

| ROI Period | 6 – 12 months |

Export sales (₹14–₹18/kg FOB) can improve ROI even further.

Why Choose FABON for 2 TPH Pellet Plants?

- Turnkey EPC Services: Design, supply, install, and commission

- Robust Ring Die Machines built for 24×7 operation

- Expertise in agro-waste & multi-feed systems

- Post-installation support & AMC plans

- Subsidy and project finance guidance

🔗 Explore: www.fabon.in/biomass-pellet-machine/

Deliverables with FABON Turnkey Package

- Pellet machine (2 TPH)

- Hammer mill

- Rotary dryer

- Cooling & bagging system

- Electrical & automation panel

- Foundation drawings

- SOP manual & operator training

- Spare parts kit

- Support with subsidy filing

Market Demand in 2025

Biomass pellets are gaining traction due to:

- NTPC and SECL’s pellet procurement programs

- Mandatory co-firing in coal plants

- Carbon credit incentives

- Global pellet export opportunities

- Growing industrial switch to biofuel boilers

Conclusion

A 2 TPH biomass pellet machine plant is a high-reward investment in India’s green energy future. With strong government support, fast-growing demand, and robust ROI potential, 2025 is the right time to enter the biomass sector.

FABON Engineering offers reliable, efficient, and cost-effective biomass pellet production systems for Indian entrepreneurs, industries, and EPC contractors.

Get Your Project Started Today

📍 FABON Engineering – India’s Leading Biomass Pellet Plant Manufacturer

🌐 Visit: www.fabon.in

📧 Email: sales@fabon.in

📞 Call: +91-9370999191 / 92267719191 / 922339191