Home > Biomass Pellet Machine

Ring Die Pellet Plant

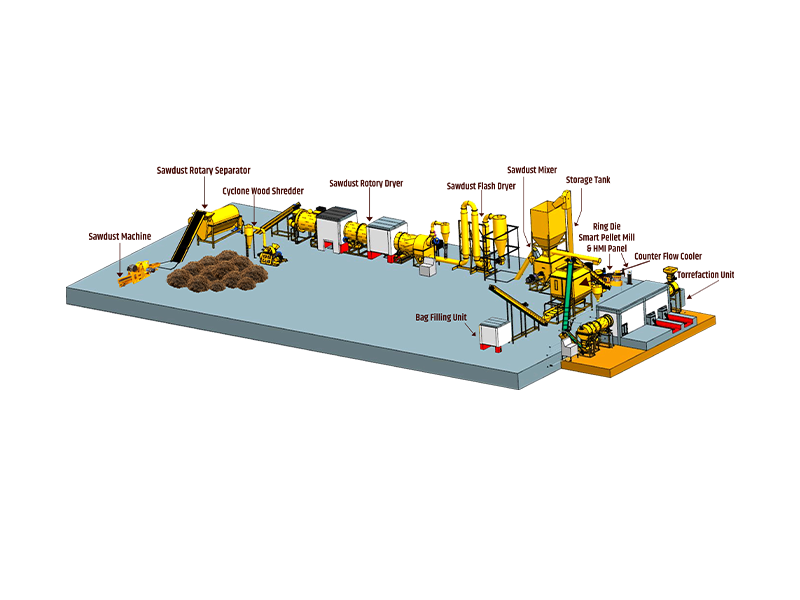

An advanced, fully automated solution for large-scale biomass pellet production. Equipped with a smart operating system, HMI panel, and real-time mobile monitoring, it ensures precision, efficiency, and seamless operation. Designed to process diverse biomass materials into high-quality pellets, it offers process optimization, data analysis, and after-sales service support for sustainable energy and industrial applications.

Read More

The Biomass Pellet Making Machine is an advanced and fully automated solution designed for large-scale biomass pellet production. This cutting-edge machine is equipped with a smart operating system, HMI panel, and real-time mobile monitoring, ensuring precise control, efficient operation, and seamless performance for optimal productivity. It is engineered to process a variety of biomass materials, transforming them into high-quality pellets that are ideal for energy generation, industrial use, and more.

The Biomass Pellet Machine features a state-of-the-art design, enabling smooth integration into large-scale production facilities. With its automation capabilities, it minimizes human intervention and maximizes production efficiency, resulting in a streamlined, cost-effective process. The smart operating system allows for easy adjustments, while the HMI panel and mobile monitoring system provide real-time data analysis, offering operators a comprehensive view of the machine’s performance and production metrics.

Thanks to its robust construction, the Biomass Pellet Machine is highly adaptable and can handle various types of biomass materials, including agricultural waste, wood chips, and forestry residues. This flexibility makes it an ideal solution for industries looking to process diverse raw materials into high-quality pellets. The machine’s versatility ensures that it delivers consistent output, with minimal downtime and optimal energy efficiency.

Key Features of the Biomass Pellet Machine:

- 1. Advanced Automation: Fully automated to ensure precision and efficiency.

- 2. Smart Operating System: Real-time mobile monitoring and easy control.

- 3. High-Quality Output: Processes diverse materials into premium biomass pellets.

- 4. Optimized Performance: Data analysis tools for process optimization and operational improvements.

- 5. Sustainable Energy Solution: Contributes to eco-friendly, renewable energy production.

The Biomass Pellet Machine is the perfect solution for businesses looking to scale up their pellet production while maintaining high standards of quality, efficiency, and sustainability.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| RD700 | 700KG/Hour | 150 HP | 15 x 45 x 20 |

| RD1000 | 1 TPH | 204 HP | 15 x 55 x 20 |

| RD2000 | 2 TPH | 348 HP | 20 x 70 x 25 |

| RD3000 | 3 TPH | 506 HP | 20 x 90 x 25 |

| RD4000 | 4 TPH | 670 HP | 20 x 90 x 30 |

| RD5000 | 5 TPH | 847 HP | 25 x 100 x 30 |

| RD6000 | 6 TPH | 940 HP | 30 x 100 x 30 |

Yulong Biomass Pellet Making Machine

Biomass pellet-making machines have gained significant popularity in India due to the rising demand for sustainable and renewable energy solutions. Yulong Biomass Pellet Making Machine is one of the leading technologies in this domain, offering advanced features and high efficiency. This blog highlights the Yulong Pellet Mill, its features, the current biomass market in India,

Read More

the selection of the perfect Yulong machine for your business, and how FABON Engineering is a trusted Yulong Pellet Machine supplier.

Yulong Biomass Pellet Mill Overview :

Yulong Machinery is a well-known brand globally for biomass pellet-making machines. The company manufactures high-performance pellet mills designed to convert biomass raw materials into high-quality fuel pellets. Yulong’s pellet mills are widely used in biomass energy plants, wood processing industries, and agricultural waste recycling units.

Key Features of Yulong Biomass Pellet Making Machine :

Advanced Ring Die Technology: Yulong pellet mills come with ring die systems that offer higher compression rates and better pellet quality.

Automatic Lubrication System: Ensures smooth operation and reduces downtime.

Energy Efficiency: Yulong machines consume less power while delivering high output.

Durable Build: Made with high-grade materials to withstand heavy-duty operations.

Smart Control Panel: Allows easy monitoring and control of the entire pellet-making process.

Versatility: Suitable for processing sawdust, agricultural waste, and other biomass materials.

Biomass Market in India :

India has seen a rapid rise in the adoption of biomass energy due to increasing environmental concerns and government incentives. Biomass pellets are widely used as an alternative fuel for industrial boilers, heating systems, and power plants. The biomass market is expected to grow exponentially in the coming years, making biomass pellet-making machines a profitable investment.

Selection of Yulong Pellet Making Machine :

When selecting a Yulong Biomass Pellet Making Machine, consider the following factors:

- Production Capacity: Choose the model based on your daily production requirements.

- Raw Material Type: Identify the types of biomass materials you plan to process.

- Energy Consumption: Opt for machines with lower power consumption and higher efficiency.

- After-Sales Support: Ensure the manufacturer provides good technical support and spare parts availability.

- Automation Level: Machines with smart automation systems offer better productivity and ease of use.

Why Choose FABON Engineering as Your Yulong Pellet Machine Supplier ?

FABON Engineering Pvt. Ltd. is a trusted Yulong Pellet Machine supplier in India, offering top-quality Yulong Biomass Pellet Making Machines with excellent after-sales support and technical assistance. With years of expertise in biomass solutions, FABON Engineering ensures reliable service, competitive pricing, and customer satisfaction. Choosing FABON Engineering guarantees seamless installation, maintenance, and long-term performance of Yulong machines.

Key Features of the Biomass Pellet Machine:

- 1. Advanced Automation: Fully automated to ensure precision and efficiency.

- 2. Smart Operating System: Real-time mobile monitoring and easy control.

- 3. High-Quality Output: Processes diverse materials into premium biomass pellets.

- 4. Optimized Performance: Data analysis tools for process optimization and operational improvements.

- 5. Sustainable Energy Solution: Contributes to eco-friendly, renewable energy production.

The Biomass Pellet Machine is the perfect solution for businesses looking to scale up their pellet production while maintaining high standards of quality, efficiency, and sustainability.

| Model | Capacity | Power (KW) |

|---|---|---|

| XGJ560 | 800-1000 Kg | 90 KW |

| XGJ560 | 1500-2000 Kg | 132 KW |

| XGJ560 | 2000-2500 Kg | 160 KW |

| XGJ850 | 3000-4000 Kg | 250 KW |

Flat Die Pellet Plant

Versatile and efficient solution for converting biomass waste into high-quality pellets. Ideal for small-scale production, this machine features a compact design, user-friendly operation, and energy efficiency. It processes materials like sawdust, agricultural residues, and forestry waste into durable biomass pellets, suitable for fuel or animal feed. Perfect for eco-friendly operations and sustainable energy solutions.The Biomass Pellet Making Machine offers a

Read More

versatile and efficient solution for converting biomass waste into high-quality pellets,making it an essential tool for small-scale production. This innovative machine is designed to process various raw materials such as sawdust, agricultural residues, and forestry waste into durable biomass pellets, which can be used for fuel or animal feed. With its compact design and energy-efficient operation, the Biomass Pellet Making Machine provides a sustainable approach to waste management and energy generation.

One of the key features of the Biomass Pellet Making Machine is its user-friendly operation. Designed for ease of use, it allows operators to quickly set up and run the machine with minimal training. Whether you’re processing wood chips, straw, or other biomass materials, this machine ensures consistent output, producing high-quality pellets with excellent durability and energy content.

The Biomass Pellet Making Machine is ideal for eco-friendly operations looking to reduce waste and promote sustainable energy solutions. By converting biomass into pellets, it helps reduce environmental impact by recycling waste products that would otherwise be discarded. These biomass pellets serve as a renewable source of energy for heating, power generation, and animal feed, making the machine a valuable asset for both commercial and industrial applications.

Key Benefits of the Biomass Pellet-Making Machine:

- 1. Efficient Processing: Converts biomass waste into high-quality pellets.

- 2. Compact and Energy-Efficient: Space-saving design and low power consumption.

- 3. Versatile Applications: Processes a wide range of raw materials.

- 4. Sustainable Solution: Reduces waste and promotes renewable energy.

- 5. User-Friendly Operation: Easy to operate with minimal training.

Investing in a Biomass Pellet Making Machine is an excellent way to enhance sustainability and promote eco-friendly practices. It provides businesses with the tools needed to create high-quality biomass pellets that can be used for energy production or animal feed. Make the move toward greener and more efficient operations with this advanced pellet-making solution.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| BM250 | 250KG/Hour | 55 HP | 30 x 45 x 20 |

| BM500 | 500KG/Hour | 80 HP | 40 x 50 x 20 |

| BM1000 | 1 TPH | 145 HP | 40 x 60 x 25 |

Torrefaction Pellet Plant

A Biomass Pellet Torrefaction Plant is an advanced facility designed to process biomass into torrefied biomass pellets, which are superior in energy content, durability, and transportability. This plant uses a controlled thermal process called torrefaction, where raw biomass materials such as wood chips, agricultural waste, or forestry residues are heated at temperatures ranging from 200°C to 300°C in the absence of oxygen.

Read More

The Biomass Pellet Mill plays a crucial role in the operation of a Biomass Pellet Torrefaction Plant. This advanced facility is specifically designed to process raw biomass materials, such as wood chips, agricultural waste, or forestry residues, into torrefied biomass pellets. These pellets are superior in energy content, durability, and transportability, making them an excellent choice for sustainable energy production.

The torrefaction process used in the Biomass Pellet Mill is a controlled thermal treatment where biomass is heated at temperatures ranging from 200°C to 300°C in the absence of oxygen. This process enhances the biomass’s physical and chemical properties, resulting in pellets that are more energy-dense, easier to store, and simpler to transport. The Biomass Pellet Mill ensures that the biomass materials are processed into uniform pellets, optimized for combustion in various industrial applications.

One of the standout features of the Biomass Pellet Mill is its ability to convert diverse raw materials into high-quality torrefied pellets. The mill provides exceptional control over the pelletizing process, ensuring consistent product quality and increased fuel efficiency. The torrefaction process significantly improves the pellets’ resistance to moisture and makes them more compact, further enhancing their value for energy production.

The Biomass Pellet Mill helps industries make the most of their biomass resources by offering an energy-efficient and environmentally friendly solution to waste management. With its advanced technology, the mill ensures higher productivity while reducing emissions, waste, and transportation costs.

Key Benefits of the Biomass Pellet Mill:

- 1. High-Energy Efficiency: Produces energy-dense torrefied pellets.

- 2. Superior Durability: Pellets have improved storage and transport properties.

- 3. Sustainability: A greener solution for biomass waste utilization.

- 4. Advanced Control: Ensures consistent pellet quality and optimized performance.

The Biomass Pellet Mill is integral to creating a sustainable and efficient biomass-to-energy cycle, enhancing both the environmental and economic viability of torrefied biomass pellets.

| Model | Capacity | Motor | Plant Size |

|---|---|---|---|

| TR1TPH | 1 TPH | 18 HP | 40x15x15 |

| TR2TPH | 2 TPH | 25 HP | 40x15x15 |