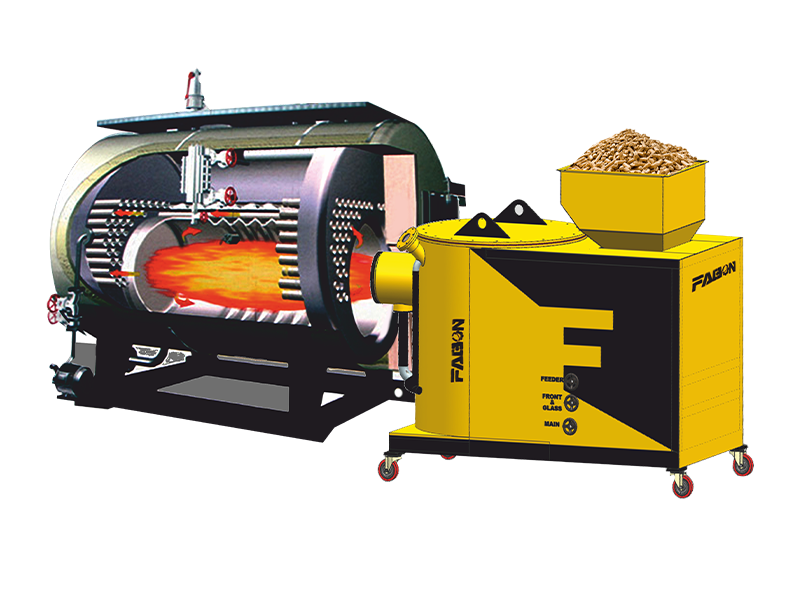

Biomass Front Fire Horizontal Pellet Burner.

The Horizontal Biomass Pellet Burner is an advanced combustion device designed for efficient and eco-friendly heating applications. It is engineered to burn biomass pellets cleanly and effectively, providing a sustainable alternative to traditional fossil fuels.

The Biomass Front Fire, also known as the Horizontal Biomass Pellet Burner, is an innovative heating solution that combines efficiency and sustainability. Designed for industrial and commercial applications, this advanced burner offers a clean and eco-friendly alternative to traditional fossil fuel systems. Utilizing biomass pellets as fuel, not only reduces environmental impact but also promotes renewable energy usage.

The Biomass Pellet Burner operates on a horizontal front-fire combustion system, ensuring uniform burning of biomass pellets. This design maximizes heat output while minimizing waste, making it a highly efficient option for heating. With its ability to maintain consistent combustion, the Biomass Front Fire ensures optimal performance, whether used in manufacturing processes, food production, or large-scale heating systems.

One of the most significant advantages of the Biomass Pellet Burner is its contribution to environmental sustainability. Using renewable biomass materials such as wood pellets or agricultural residues, helps lower carbon emissions and reduce reliance on non-renewable resources. Additionally, its efficient combustion process results in lower operational costs, making it an economically viable option for businesses.

Key Benefits of Biomass Front Fire and Biomass Pellet Burner:

- 1. Eco-Friendly Heating: Reduces carbon footprint with renewable biomass pellets.

- 2. High Efficiency: Horizontal combustion ensures consistent and effective heating.

- 3. Cost-Effective: Lower energy costs due to efficient fuel usage.

- 4. Versatile Applications: Suitable for industrial, commercial, and agricultural needs.

- 5. Sustainability: Promotes renewable energy adoption and reduces environmental impact.

By investing in a Biomass Front Fire or Biomass Pellet Burner, industries can achieve efficient heating with minimal environmental impact. This horizontal burner system delivers sustainable energy solutions, making it an ideal choice for those looking to enhance efficiency and embrace eco-friendly practices. Transition to the Biomass Front Fire today for reliable, clean, and sustainable heating!

| Model | Capacity | Power |

|---|---|---|

| BRH1KC | 1 Lakh Kcal | 0.5 HP |

| BRH2KC | 2 Lakh Kcal | 1.5 HP |

| BRH4KC | 4 Lakh Kcal | 2.5 Hp |

| BRH6KC | 6 Lakh Kcal | 2.5 Hp |

| BRH8KC | 8 Lakh Kcal | 4 Hp |

| BRH10KC | 10 Lakh Kcal | 4 Hp |

Fabon Engineering’s Biomass Front Fire Horizontal Pellet Burner: Efficient, Sustainable Heating for Industry

As industries increasingly seek out cost-effective and eco-conscious energy solutions, Fabon Engineering, based in Nashik, Maharashtra, has introduced an advanced and highly efficient heating system — the Biomass Front Fire Horizontal Pellet Burner. This burner combines robust design, clean energy, and low operational costs, making it ideal for a wide range of industrial heating applications.

A Smart Alternative to Conventional Fuels

The Front Fire Horizontal Pellet Burner by Fabon operates on biomass pellets, a renewable fuel made from organic waste such as sawdust, agricultural residues, and wood chips. This eco-friendly fuel is not only carbon-neutral but also significantly more cost-effective than diesel, furnace oil, or LPG.

The horizontal front-fire design is engineered for high thermal output and easy integration with existing systems like boilers, ovens, hot air generators, and furnaces. It is especially well-suited for industries that require a steady and direct flame with uniform heat distribution.

Key Features of the Front Fire Horizontal Pellet Burner

✅ High Combustion Efficiency: Achieves up to 90% fuel combustion, maximizing energy output while minimizing pellet consumption.

✅ Front-Fire Design: Ensures uniform flame projection and easy alignment with industrial heating systems.

✅ Automatic Pellet Feeding: Reduces labor costs and ensures uninterrupted operation.

✅ Digital Control Panel: Simplifies burner operation and allows real-time monitoring of temperature and fuel usage.

✅ Low Maintenance: Designed with accessible components for easy cleaning and servicing.

✅ Compatible with Smoke Collectors: Can be integrated with Fabon’s smoke collector system for pollution control.

Why Choose Fabon’s Horizontal Pellet Burner?

Fabon Engineering’s burner is more than just a heating device—it’s a commitment to sustainability. The burner offers:

🔥 Cleaner combustion compared to fossil fuels

🌱 Lower CO₂ emissions

💰 Reduced operational costs

🧩 Customizable capacities based on industrial needs

🛠 Local manufacturing and support from a trusted Indian engineering firm

Ideal Applications Across Industries

The Biomass Front Fire Horizontal Pellet Burner is suitable for:

Boilers and steam generation

Food processing ovens

Ceramic kilns

Chemical processing units

Textile dryers

Any industrial process requiring consistent, high-temperature heat

FAQs – Biomass Front Fire Horizontal Pellet Burner

1. What is a Biomass Front Fire Horizontal Pellet Burner?

It is an industrial heating system designed to burn biomass pellets using a front-facing horizontal flame. This configuration ensures direct, uniform heat and is ideal for boilers, ovens, dryers, and other thermal systems.

2. What kind of fuel does it use?

It runs on biomass pellets, which are compressed forms of organic materials such as sawdust, wood chips, rice husk, and other agricultural residues.

3. What is the benefit of the horizontal front-fire design?

The horizontal flame projection aligns easily with existing furnace or boiler openings, ensuring efficient heat transfer, better flame direction control, and simplified installation.

4. What are the main advantages of this burner?

High thermal efficiency (up to 90%)

Uniform heat distribution

Reduced operating costs

Eco-friendly and carbon-neutral operation

Easy integration with existing systems

Optional smoke collector compatibility for pollution control

5. How does the automatic feeding system work?

The burner includes an automated pellet feeder that draws pellets from a storage hopper and feeds them into the combustion chamber at controlled intervals, ensuring continuous operation and reducing manual labor.

6. Is the burner environmentally friendly?

Yes. The burner produces very low particulate and gaseous emissions and can be paired with a smoke collector system to meet pollution control norms set by the CPCB and SPCBs.

7. What industries is this burner suitable for?

This burner is ideal for:

Food processing

Chemical manufacturing

Steam boilers

Textile drying

Ceramic and metal furnaces

General industrial heating

8. Can it replace diesel or gas burners?

Absolutely. Fabon’s pellet burner is a cost-effective and sustainable alternative to diesel, furnace oil, and LPG burners, often achieving 30–60% fuel cost savings.

9. Is the system customizable?

Yes. Fabon Engineering offers customizable capacity options based on your thermal load, fuel availability, and application needs.

10. What kind of maintenance is required?

Routine maintenance includes:

Ash removal

Periodic cleaning of the combustion chamber

Checking and cleaning the feeding system

Monitoring control panel functions

Fabon provides maintenance support and operational training as part of their service.

11. Is technical support available?

Yes. Fabon Engineering offers installation, training, and after-sales technical support, including remote and on-site assistance.

12. Where is Fabon Engineering located?

Fabon Engineering is based in Nashik, Maharashtra, and supplies its equipment across India and internationally.

13. How can I get pricing or technical specifications?

You can reach out to Fabon Engineering through their website, phone, or email to get a customized quote and technical consultation.