Home > Biomass Dryer

Rotary Dryer

The Rotary Dryer from FABON Engineering Pvt. Ltd. is an innovative drying solution designed to handle a wide range of materials with precision and efficiency. Perfect for biomass, agricultural, and industrial applications, this dryer ensures uniform drying and high output quality.

Read More

The Biomass Sawdust Dryer by FABON Engineering Pvt. Ltd. is an advanced rotary drying system designed to meet the diverse needs of biomass, agricultural, and industrial applications. This innovative dryer ensures precise and uniform drying for materials such as sawdust, wood chips, agricultural residues, and other biomass products, making it a critical component in biomass fuel production and industrial processes.

With its cutting-edge design, the Biomass Sawdust Dryer uses a rotating drum and optimized airflow technology to reduce moisture content effectively. This controlled drying process enhances the quality of materials, preparing them for applications like pellet production, combustion, or safe storage.

Key Features of Biomass Sawdust Dryer

- 1. Energy Efficiency: Engineered to minimize energy consumption while delivering superior drying performance, reducing operational costs.

- 2. Uniform Drying: Advanced airflow technology ensures consistent drying across all material types for optimal results.

- 3. Robust Construction: Built with high-quality materials, this dryer offers durability and long service life, even in demanding industrial environments.

- 4. Versatile Applications: Suitable for drying various biomass materials, including sawdust, wood chips, and agricultural residues.

- 5. Eco-Friendly Design: Supports sustainable operations by efficiently utilizing biomass materials and reducing waste.

- 6. Low Maintenance: Requires minimal maintenance due to its reliable and user-friendly design.

- 7. High Throughput: Designed for industrial-scale operations, ensuring maximum productivity.

The Biomass Sawdust Dryer is an indispensable tool for businesses aiming to improve their biomass processing operations. Whether you’re in the biomass energy sector or industrial manufacturing, this dryer ensures materials are dried to the precise moisture level required for optimal performance and storage.

| Model | Capacity | Motor |

|---|---|---|

| RDR100 | 1 TPH | 20 HP |

| RDR200 | 2 TPH | 30 HP |

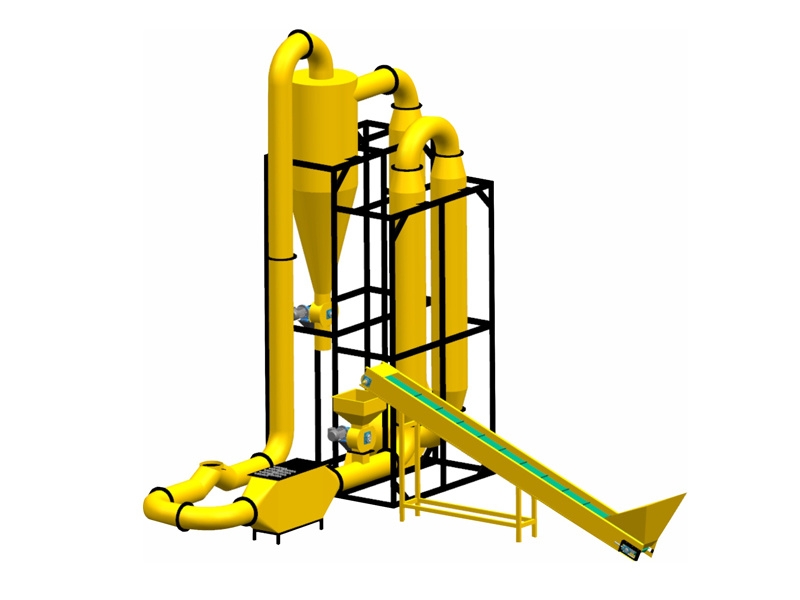

Flash Dryer

The Flash Dryer by FABON Engineering Pvt. Ltd. is a state-of-the-art drying system designed to reduce moisture content in biomass materials quickly and efficiently. Ideal for industries involved in biomass pellet production, this dryer ensures consistent quality and high productivity.

Read More

The Sawdust Dryer by FABON Engineering Pvt. Ltd. is a cutting-edge flash drying system designed to optimize moisture reduction in biomass materials. Engineered for efficiency and speed, this innovative dryer is the perfect solution for industries involved in biomass pellet production, offering consistent quality and unmatched productivity. Whether it’s sawdust, wood chips, or agricultural residues, this Sawdust Dryer ensures high-quality output suitable for fuel, pellet production, and other industrial applications.

What sets the Sawdust Dryer apart is its ability to handle large volumes of material while maintaining uniform moisture reduction. By employing flash drying technology, it rapidly heats and dries biomass, significantly reducing processing time compared to traditional drying methods. This not only enhances productivity but also ensures that the material retains its quality and structure throughout the process.

Key Features of the Sawdust Dryer

- 1. High Efficiency: The flash drying technology allows for rapid drying, ensuring minimal energy consumption while delivering consistent results.

- 2. Versatility: Designed to handle various biomass materials, including sawdust, wood chips, and agricultural residues.

- 3. Compact Design: Its space-saving design makes it an ideal choice for industries with limited operational space.

- 4. Energy-Saving Operation: Reduces energy usage, leading to cost savings and environmental benefits.

- 5. Advanced Controls: Equipped with user-friendly controls for precise temperature and moisture level monitoring.

- 6. Durable Construction: Built with high-quality materials to ensure longevity and reliability in demanding industrial environments.

With FABON’s Sawdust Dryer, businesses can achieve superior drying performance, reduce operational costs, and support eco-friendly practices. Whether you’re producing biomass pellets or other materials, this efficient dryer is your trusted partner for high-quality results. Trust FABON Engineering Pvt. Ltd. to deliver innovative solutions for all your biomass drying needs.

| Model | Capacity | Motor |

|---|---|---|

| DR050 | 500 Kg / Hour | 15 HP |

| DR100 | 1 TPH | 20 HP |

| DR200 | 2 TPH | 30 HP |

Horizontal Dryer

A horizontal dryer is an industrial drying equipment designed to efficiently remove moisture from various materials, such as chemicals, food products, and pharmaceuticals. It operates by circulating heated air or gas horizontally over the material, which is typically spread in a thin layer on a moving conveyor or drum inside the dryer. The continuous flow of hot air helps evaporate moisture, while the horizontal orientation ensures uniform drying across the material. Horizontal dryers are valued for their energy efficiency, high throughput, and ability to handle large volumes of materials, making them ideal for large-scale drying applications in industries like food processing, mining, and chemical production.

Read More

The Horizontal Dryer is a cutting-edge industrial drying system designed to remove moisture efficiently from a wide range of materials, including biomass, sawdust, and agricultural residues. Engineered for precision and high performance, this dryer is an excellent choice for large-scale drying applications in industries such as biomass pellet production, food processing, and chemical manufacturing. The system uses a horizontal design, where heated air flows uniformly over the material spread on a conveyor or drum, ensuring consistent and rapid drying.

FABON Engineering Pvt. Ltd. has introduced the Horizontal Dryer as a specialized solution for biomass drying. With its advanced design, it is especially effective as a Sawdust Dryer and Biomass Sawdust Dryer, helping to reduce moisture content efficiently. This optimized drying process enhances the quality and usability of biomass materials, making them suitable for pellet production, fuel, or industrial applications.

Key Features of the Horizontal Dryer

- 1. Uniform Drying: The horizontal air circulation ensures consistent drying across all materials, reducing variations in moisture content.

- 2. Energy Efficiency: Designed to minimize energy consumption, saving operational costs while maintaining high performance.

- 3. High Throughput: Capable of handling large volumes of biomass and sawdust, making it suitable for large-scale operations.

- 4. Durable Design: Built with robust materials to withstand industrial demands and ensure long-term reliability.

- 5. Advanced Controls: Features precise temperature and moisture monitoring for optimal drying conditions.

- 6. Versatility: Ideal for drying various materials, including sawdust, wood chips, chemicals, and agricultural residues.

The Horizontal Dryer by FABON Engineering Pvt. Ltd. is the perfect solution for industries aiming to streamline their drying processes. Whether you need a Sawdust Dryer or a Biomass Sawdust Dryer, this advanced equipment guarantees consistent results, reduced energy consumption, and enhanced productivity. Choose FABON for innovative and sustainable drying solutions.

| Model | Capacity | Motor |

|---|---|---|

| DR050 | 500 Kg / Hour | 15 HP |

| DR100 | 1 TPH | 20 HP |

| DR200 | 2 TPH | 30 HP |