Home > Sawdust Machine

Sawdust Making Machine

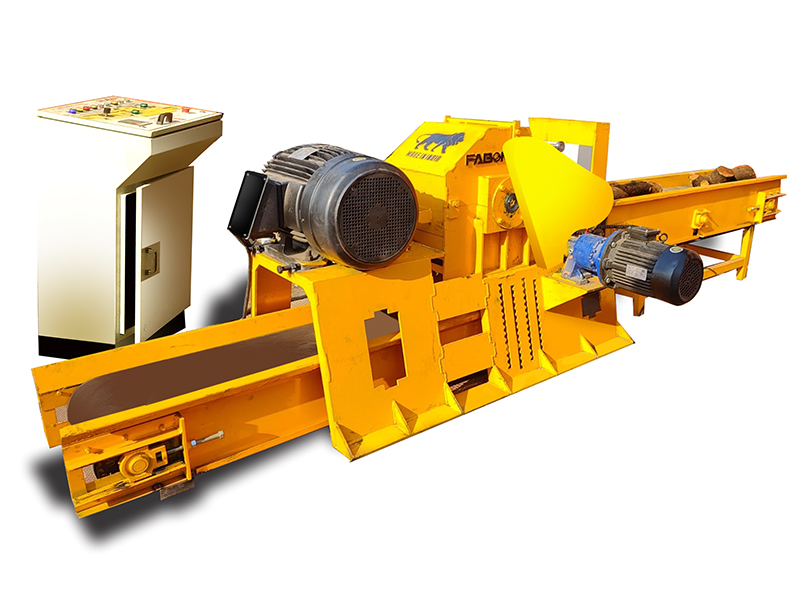

The Biomass Sawdust Making Machine is the ultimate solution for converting wood waste, agricultural residues, and other biomass materials into high-quality sawdust. Designed by FABON Engineering Pvt. Ltd., India’s leading biomass machinery manufacturer, this innovative machine ensures efficiency, reliability, and sustainability.

Read More

The Biomass Sawdust Dryer is an essential component when utilizing the Biomass Sawdust Making Machine. This advanced machinery is specifically designed to convert wood waste, agricultural residues, and other biomass materials into high-quality sawdust. Manufactured by FABON Engineering Pvt. Ltd., a leader in biomass machinery manufacturing in India, the Biomass Sawdust Dryer ensures that the sawdust produced is properly dried, offering enhanced quality and energy efficiency.

After the Biomass Sawdust Making Machine processes raw materials into sawdust, the next step is to ensure that it is appropriately dried to maintain its energy value and usability. The Biomass Sawdust Dryer performs this critical function by efficiently reducing moisture content, making the sawdust suitable for further processing or use as biomass fuel. This helps ensure that the sawdust remains free of mold or decomposition during storage and transport.

The Biomass Sawdust Dryer works in tandem with the Biomass Sawdust Making Machine, making it a perfect solution for industries focusing on biomass processing. The drying process also helps in improving the combustion quality of the sawdust when used in various applications, such as biomass fuel, animal bedding, or even as a raw material for other pelletizing processes.

FABON Engineering’s Biomass Sawdust Dryer is designed with energy efficiency in mind. It uses advanced drying technologies to ensure that the sawdust is evenly dried while minimizing energy consumption. This ensures that businesses can achieve high output without high operational costs, making the Biomass Sawdust Dryer a sustainable choice for biomass operations.

Key benefits of the Biomass Sawdust Dryer:

- 1. Efficient Moisture Reduction: Ensures sawdust is properly dried for optimal quality.

- 2. Energy Efficiency: Designed to minimize energy usage during the drying process.

- 3. Increased Product Usability: Prepares sawdust for a variety of applications.

- 4. Sustainable Solution: Helps improve biomass processing operations by utilizing waste effectively.

Together, the Biomass Sawdust Making Machine and Biomass Sawdust Dryer provide a complete, efficient, and eco-friendly solution for transforming biomass waste into valuable products.

| Model | Capacity | Motor |

|---|---|---|

| SD100 | 500 Kg / Hour | 15 HP |

| SD200 | 1 TPH | 30 HP |

Wood Shredder

The Wood Shredder from FABON Engineering Pvt. Ltd. is a cutting-edge machine designed to shred wood waste into manageable sizes, paving the way for efficient recycling and biomass processing. Built with precision engineering, this machine is a must-have for industries focused on sustainability and productivity.The Wood Shredder from

Read More

FABON Engineering Pvt. Ltd. is a state-of-the-art machine designed for efficiently shredding wood waste into manageable sizes, enabling better recycling and biomass processing. This machine is a crucial component for industries that aim to improve sustainability while maintaining high productivity levels.

The Wood Shredder is engineered to handle a wide variety of wood materials, including branches, logs, and wood chips. Its ability to reduce large volumes of wood into smaller, uniform pieces makes it an essential tool in biomass production. The shredded wood can be further processed into high-quality sawdust or used as a raw material for other industrial applications, such as biomass fuel.

When combined with the Sawdust Machine, the Wood Shredder plays a key role in the biomass processing chain. The Sawdust Machine can convert the shredded wood into fine, high-quality sawdust, which can then be used in numerous applications like animal bedding, fuel production, and even pelletizing. Together, the Wood Shredder and Sawdust Machine create an integrated solution for industries looking to optimize their biomass waste management and enhance the value of their materials.

The Wood Shredder is built with precision engineering and robust construction to ensure long-lasting performance and reliable operation. It features advanced safety measures and is designed to minimize downtime, allowing for continuous processing. This makes it an ideal investment for industries focused on sustainability and reducing environmental impact.

Key Benefits of the Wood Shredder:

- 1. Efficient Waste Processing: Reduces wood waste into manageable sizes for further processing.

- 2. Sustainability: Plays a crucial role in recycling and converting wood waste into valuable products.

- 3. Versatility: Works seamlessly with the Sawdust Machine to produce high-quality sawdust for various applications.

- 4. Durability: Built to last with precision engineering and advanced safety features.

The Wood Shredder is an indispensable part of the biomass processing process, providing industries with an efficient, cost-effective solution for managing wood waste and producing high-value products like sawdust.

| Model | Capacity | Motor |

|---|---|---|

| WS400 | 500 Kg / Hour | 15 HP |

| WS600 | 1 TPH | 30 HP |

| CWS400 | 500 Kg / Hour | 20 HP |

| CWS600 | 1 TPH | 40 HP |

Hammer Mill

A hammer mill is a versatile and efficient industrial machine used for crushing, grinding, and pulverizing various materials into smaller particles. It operates by using high-speed rotating hammers to impact the material, breaking it down into the desired size. Hammer mills are widely used in industries such as agriculture, food processing, chemical manufacturing, and recycling, for tasks like grinding grains, shredding wood, and producing powders. The size of the output material can be controlled by adjusting the screen size and hammer configuration, making hammer mills adaptable to a wide range of processing needs.The Hammer Mill is a crucial machine in various industries, particularly for those involved in biomass

Read More

processing, agriculture, and recycling. One of its key uses is in conjunction with Sawdust Making Machines, where it helps in breaking down wood and other raw materials into smaller particles that can be processed into sawdust. This makes the Hammer Mill an indispensable tool for businesses looking to optimize the sawdust production process.

As part of a comprehensive biomass processing setup, the Hammer Mill operates by using high-speed rotating hammers to impact the material, crushing and grinding it into smaller, more manageable particles. These particles, or sawdust, can then be further processed for various applications, such as biomass fuel, animal bedding, and more. When combined with a Sawdust Making Machine, the Hammer Mill provides an effective and efficient means of breaking down large wood pieces, creating fine sawdust that can be used in other production processes.

Once the sawdust is produced, it is important to ensure it has the proper moisture content for storage and further processing. This is where the Sawdust Dryer comes into play. After the Sawdust Making Machine generates the sawdust, the Sawdust Dryer removes excess moisture, ensuring that the sawdust is dry and suitable for various uses, including fuel and feedstock.

The Sawdust Dryer works seamlessly with the Hammer Mill and Sawdust Making Machine, creating an integrated system for producing high-quality sawdust efficiently. Businesses that use these machines in tandem can streamline their operations and reduce waste, while also ensuring that the output is suitable for commercial use.

Key benefits of the Hammer Mill:

- 1. Versatile: Suitable for grinding various materials such as wood, grains, and biomass.

- 2. Efficient Sawdust Production: Works in synergy with Sawdust Making Machines to break down raw materials into fine sawdust.

- 3. Easy to Adjust: The output material size can be controlled by adjusting the hammer configuration and screen size, making it adaptable for different applications.

When paired with a Sawdust Dryer, the Hammer Mill ensures that sawdust is not only produced efficiently but also dried to optimal levels for further processing and use.

| Model | Capacity | Motor |

|---|---|---|

| HM200 | 250 KG/Hour | 7.5 HP |

| HM300 | 500 KG/Hour | 15 HP |

| HM400 | 1 TPH | 30 HP |

| HM500 | 2 TPH | 50 HP |

Napier Grass Dewatering Machine

Looking for an efficient solution to dewater Napier grass for biomass production? Our Napier Dewatering Machine is your ideal choice! Specially designed to handle high-moisture content, this cutting-edge machine optimizes the moisture reduction process, preparing Napier grass for pelletizing, briquetting, or further biomass processing.

Why Choose Our Dewatering Machine for Biomass Solutions? Our machine helps biomass producers maximize productivity while reducing processing time and energy costs. It ensures uniform drying and high-quality output for biofuel production, making it an essential part of sustainable biomass solutions.

Read More

The Hammer Mill is a crucial machine in various industries, particularly for those involved in biomass processing, agriculture, and recycling. One of its key uses is in conjunction with Sawdust Making Machines, where it helps in breaking down wood and other raw materials into smaller particles that can be processed into sawdust. This makes the Hammer Mill an indispensable tool for businesses looking to optimize the sawdust production process.

As part of a comprehensive biomass processing setup, the Hammer Mill operates by using high-speed rotating hammers to impact the material, crushing and grinding it into smaller, more manageable particles. These particles, or sawdust, can then be further processed for various applications, such as biomass fuel, animal bedding, and more. When combined with a Sawdust Making Machine, the Hammer Mill provides an effective and efficient means of breaking down large wood pieces, creating fine sawdust that can be used in other production processes.

Once the sawdust is produced, it is important to ensure it has the proper moisture content for storage and further processing. This is where the Sawdust Dryer comes into play. After the Sawdust Making Machine generates the sawdust, the Sawdust Dryer removes excess moisture, ensuring that the sawdust is dry and suitable for various uses, including fuel and feedstock.

The Sawdust Dryer works seamlessly with the Hammer Mill and Sawdust Making Machine, creating an integrated system for producing high-quality sawdust efficiently. Businesses that use these machines in tandem can streamline their operations and reduce waste, while also ensuring that the output is suitable for commercial use.

Key benefits of the Hammer Mill:

- 1. Versatile: Suitable for grinding various materials such as wood, grains, and biomass.

- 2. Efficient Sawdust Production: Works in synergy with Sawdust Making Machines to break down raw materials into fine sawdust.

- 3. Easy to Adjust: The output material size can be controlled by adjusting the hammer configuration and screen size, making it adaptable for different applications.

When paired with a Sawdust Dryer, the Hammer Mill ensures that sawdust is not only produced efficiently but also dried to optimal levels for further processing and use.

| Model | Capacity | Motor |

|---|---|---|

| HM200 | 250 KG/Hour | 7.5 HP |

| HM300 | 500 KG/Hour | 15 HP |

| HM400 | 1 TPH | 30 HP |

| HM500 | 2 TPH | 50 HP |